Components of oil drill pipe hardening and tempering production line

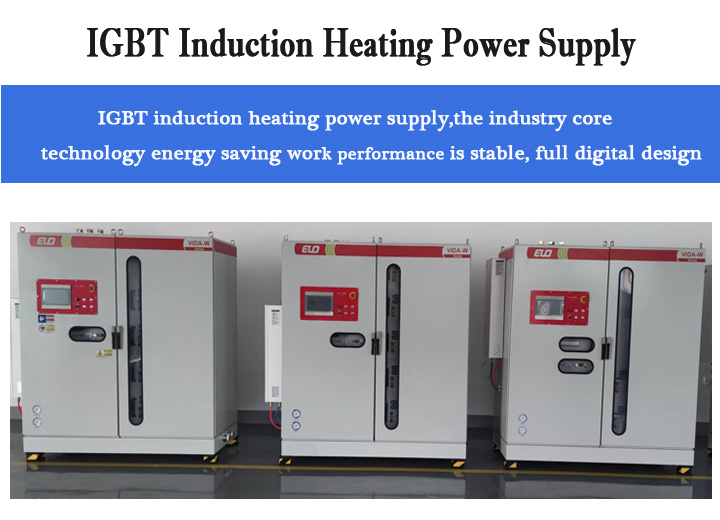

Induction heating power supply: provides high-frequency or medium frequency alternating current to ensure that the induction coil generates a stable magnetic field.

Induction coil: It is the main executing component of heating equipment, and its design needs to be customized according to the specifications of the oil casing to ensure uniform heating on the surface and inside of the casing.

Water cooling system: During the induction heating process, a large amount of heat is generated. The water cooling system ensures the stability of equipment operation by circulating water cooling induction coils and power components.

Control system: It can accurately adjust the heating temperature, time, and power to meet the processing requirements of different petroleum casings and improve production efficiency.

The process of oil casing pipe heat treatment furnace

Quenching: Heating the oil casing to the quenching temperature and rapidly cooling it to improve hardness and wear resistance.

Tempering: Slowly heat and gradually cool to eliminate internal stress and improve mechanical properties.

Quenching and tempering: Heating to a lower temperature after quenching reduces brittleness and improves toughness.

Advantages of Pipeline induction heat treatment furnace

Efficient and energy-saving: Induction heating equipment directly heats oil casing through electromagnetic induction, greatly reducing heat loss and achieving an energy efficiency conversion rate of over 90%.

Accurate temperature control: The control system can monitor the temperature of the casing in real time to ensure that the heating process reaches the precise temperature range required by the process, avoiding overheating or underheating phenomena.

Strong applicability: Induction heat treatment furnaces can adapt to the processing needs of different materials (such as carbon steel, stainless steel, alloy steel) and specifications of petroleum casing, with high flexibility.

Environmentally friendly: The induction heating process has no open flames, no exhaust gas or dust emissions, meeting the requirements of modern industrial green manufacturing.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-18-2024