The Forever Steel Pipe and oil casing pipe heat treatment furnace is an equipment produced by Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. for the heat treatment of steel pipes and oil casings.

oil pipeline induction heat treatment production line Equipment Composition

Power supply system: quenching 750-3500KW/0.5-4KHz, tempering 400-1600KW/0.5-2.5KHz.

Conveyor roller conveyor: The axis of the roller conveyor forms an angle of 18-21 ° with the axis of the workpiece, making heating more uniform. The roller conveyor between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled.

Feeding system: Each axis is driven by an independent motor reducer, controlled by an independent frequency converter, and can flexibly design speed difference output, with segmented control of operating speed.

Formula management system: powerful formula management function, automatically calls relevant parameters after inputting the steel grade, outer diameter, and wall thickness parameters to be produced.

Multi channel closed-loop system: A high-level temperature, voltage and other multi-channel closed-loop system has been designed to address the instability of the power supply system.

Equipment features of the oil drill pipe hardening and tempering production line

Uniform heating temperature: Using medium frequency induction heating technology, it can achieve uniform heating of steel pipes, with small temperature difference between the core and surface, ensuring the quality of heat treatment.

High degree of automation: equipped with temperature closed-loop, intelligent, PLC total operation control system, it can achieve automated and intelligent induction heating, reduce manual intervention, improve production efficiency and product quality stability.

Environmentally friendly and pollution-free: There will be no harmful gases, smoke, or other environmental pollutants during the production process.

High energy conversion efficiency: using quenching+tempering method, with a power consumption of 450-550 kWh per ton, the energy-saving effect is significant.

Wide applicability: The range of steel pipe specifications that can be processed is ø 20 ø 1000, with a wall thickness of 2.5mm-10mm.

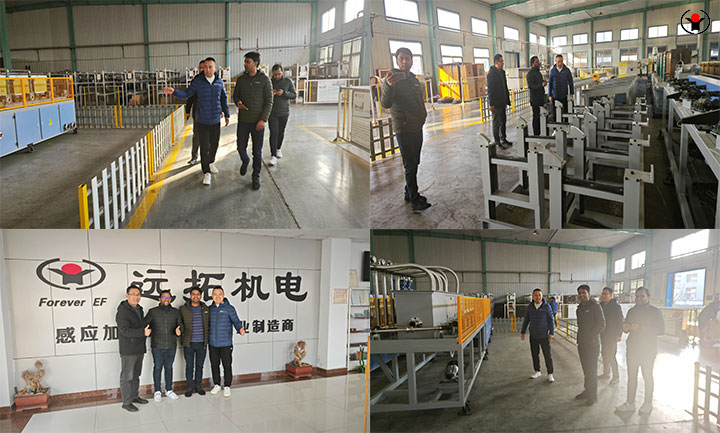

The Forever steel pipe oil casing heat treatment production line has been applied in multiple domestic steel bar quenching and tempering production lines and exported to Indonesia, Russia, India, Vietnam, Africa, Taiwan, Argentina, Serbia, Iran, Central Asia and other regions. The product quality is stable and well received by users.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-18-2025