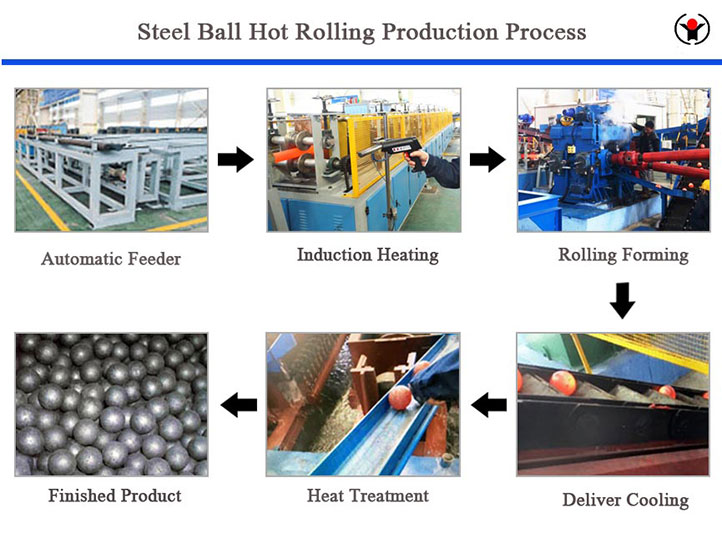

The steel ball hot rolling production line is designed by Forever specifically for the steel ball rolling process. Mainly used for precise heating and rolling of various steel raw materials. The system supports a power range of 200 kW to 6000 kW, or uses IGBT modules with a power range of 200 kW to 2000 kW. The hourly output can reach 0.2 to 16 tons, and the sensor adopts variable pitch and temperature gradient design to improve heating efficiency and achieve precise temperature control.

The steel ball induction hot rolling system is equipped with elastic adjustable pressure rollers to adapt to round steel bars of different diameters, allowing the steel bars to feed at a constant speed. The pressure roller and roller ticket are made of 304 non-magnetic stainless steel and equipped with a water cooling system. The discharge end is equipped with an infrared temperature measurement device to ensure that the temperature of the steel rod is consistent before entering the rolling mill.

The steel ball hot rolling heating furnace has the following advantages:

Fast heating speed: The Heating furnace for steel ball hot rolling adopts medium frequency induction heating method, which generates heat inside the workpiece itself, with fast heating speed, minimal oxidation, high heating efficiency, significantly shortens heating time, and improves production efficiency.

Energy saving and environmental protection: During the heating process, there is minimal energy loss, high thermal efficiency, and reduced energy waste. Additionally, there are no open flames or smoke, resulting in minimal environmental pollution and meeting the requirements of modern industrial green development.

Uniform heating: By selecting a reasonable working frequency and adjusting the appropriate heat transfer depth, uniform heating can be achieved with a small temperature difference between the core and surface, ensuring the quality of heat treatment of the steel ball and making the hardness of the steel ball uniform and consistent. The difference between the outer hardness and the inner hardness is small.

Precise control: It can accurately control the heating temperature, heating time, and heating area to meet the requirements of different processes for heating accuracy and ensure stable product quality.

Fully automatic operation: It can achieve fully automatic unmanned operation, using automatic feeding and discharging sorting devices, and equipped with dedicated control software. The entire process from raw materials to finished products is almost unmanned, reducing production costs and improving the production environment.

Easy to integrate: can be combined with automation equipment to achieve automation and intelligence of production lines, improving production efficiency and quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-21-2025