In this high-tech era, intelligent control is no longer a rarity, but rather feels a bit out of place without intelligence. The development of steel bar heat treatment heating furnaces in the metal workpiece heat treatment industry has now achieved full intelligent control. Have you achieved the heat treatment equipment you are currently using?

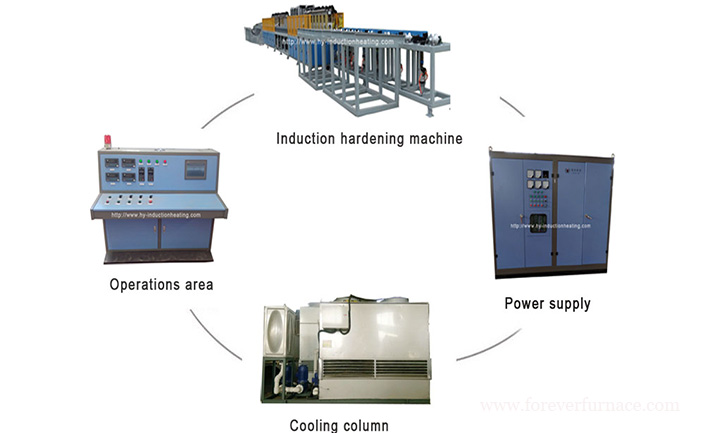

Long bar induction heat treatment machine

Forever has years of rich experience in the induction heat treatment industry, and has developed a fully intelligent steel bar heat treatment heating furnace and other induction heat treatment production lines that are stable, cost saving, and high production efficiency.

Today, let’s talk about the relationship between PLC intelligent control and variable frequency control of Long bar induction heat treatment machine ?

1. The Medium frequency induction heating equipment is controlled by an intelligent human-machine interface touch screen PLC control cabinet, mainly used for logic control, as well as flow control of medium mechanical actions during the working process of the induction heat treatment equipment.

2. Adopting a variable frequency control cabinet control system, it can protect the power device and have a soft start function.

In practical applications, PLC controllers are also integrated into frequency conversion control cabinets. The variable frequency control cabinet can also be controlled by PLC, but more emphasis is placed on the variable frequency speed regulation function. Ensure stable performance of induction heat treatment equipment.

Currently, inverters are increasingly used in control systems for automation, intelligence, and induction heat treatment equipment. As a professional provider of induction heat treatment equipment such as steel rod tempering production lines, Yuantuo’s engineers will customize induction heat treatment quenching and tempering production line equipment to meet your process needs and work requirements.

Using Forever Electromechanical Automation Intelligent Induction Heating Heat Treatment Equipment can save you costs and labor costs, and improve production capacity. Find a professional engineer to solve problems related to the heating and tempering furnace for steel bar heat treatment

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !

Post time: 08-07-2023