Yuantuo Electromechanical Threaded rod heat treatment machine replaces traditional heating methods such as oxyacetylene flame, coke oven, salt bath furnace, gas furnace, oil furnace, etc. We have achieved environmental protection and energy conservation in the heat treatment production line, as well as a more stable working guarantee.

Yuantuo Electromechanical’s Long bar heat treatment QT machine adopts IGBT as the main component and full bridge inverter. High standard load duration design, capable of continuous operation. Complete protection function and high reliability. It can be remotely controlled and equipped with infrared temperature measurement to achieve automatic temperature control, improve heating quality, and simplify worker operations. Adopting frequency automatic follow-up and multi-channel closed-loop control, it is easy to install and operate.

The new long bar induction hardening and tempering fruance , which is safe and energy-saving, adopts modern automated green energy-saving induction heating method. The production process adopts the fully intelligent steel bar quenching and tempering production line independently developed by Yuantuo Electromechanical, advanced temperature control device and supporting heat treatment equipment, and uses specially developed wear-resistant materials for production. By utilizing advanced steel bar quenching and tempering equipment, the hardness of ordinary round steel with a hardness of around HRC10-15 is directly increased to a high hardness after heat treatment, and then further treated with heat treatment technology to a hardness range of HRC45-5.

The Yuantuo Electromechanical Long bar induction heat treatment system is fully automated, and the steel rod quenching and tempering heat treatment is fully controlled by microcomputer integration. During production, only the buttons corresponding to different materials need to be activated to automate the production. The temperature between each link and point in the production line can be displayed and controlled on the PLC display screen. The steel rod quenching layer is thicker, and the steel rod heat-treated on this production line is more uniform than ordinary wear-resistant steel rods. The hardness of each part of the steel rod is uniform, completely eliminating the problems of inconsistent hardness and oxide scale in various parts of the heat-treated steel rod, further reducing wear and breakage rates.

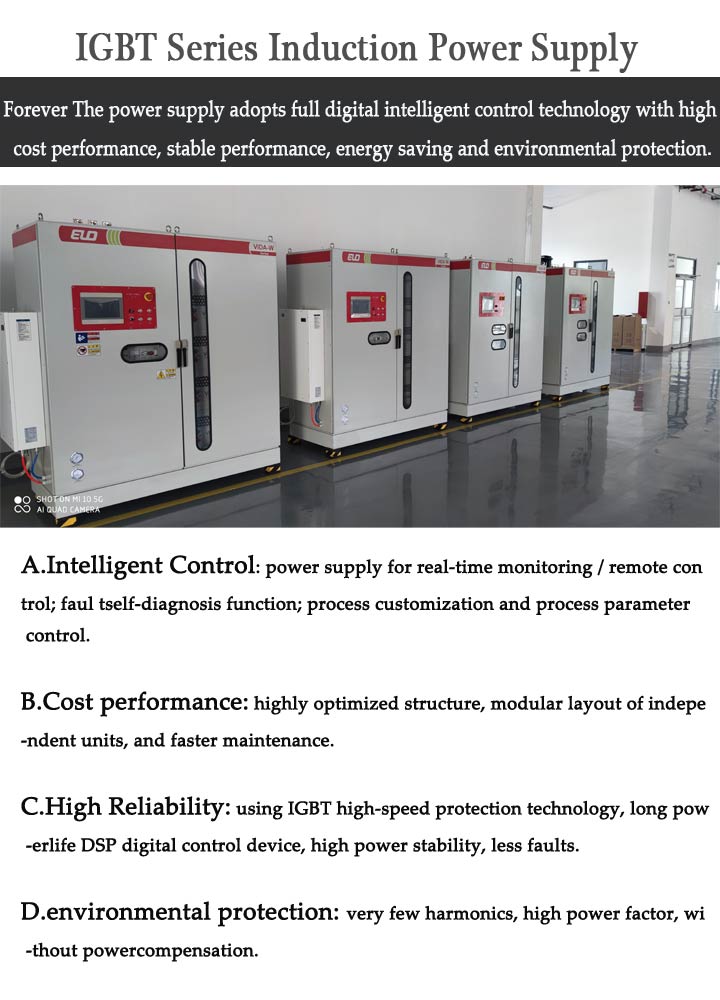

we also have IGBT Induction heating power supply

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-21-2025