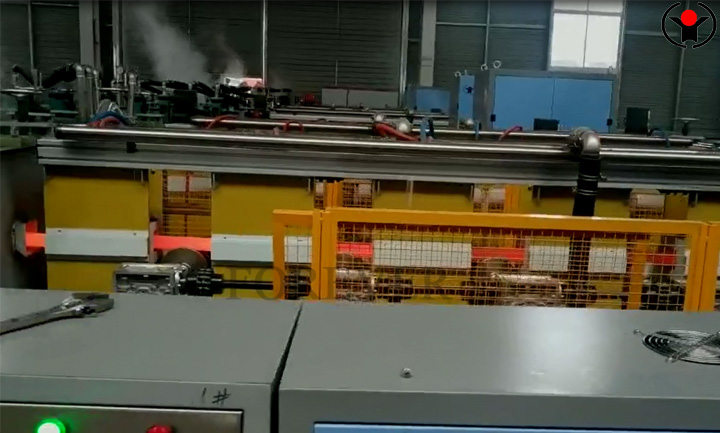

The common heating methods for steel pipe hardening and tempering furnace include medium frequency induction heating and high-frequency induction heating. Medium frequency induction heating is suitable for most square tube processing, especially for stable performance during the quenching process of large-sized square tubes; High frequency induction heating is suitable for small-sized square tubes and can quickly heat to the desired temperature. Hebei Forever Electromechanical provides customized heating solutions according to the needs of different square tubes to ensure the uniformity and efficiency of heating effects.

What is the cooling method of the square tube quenching treatment line?

There are usually two cooling methods: water cooling and oil cooling. Water cooling is suitable for square tubes with high hardness requirements, which can quickly remove heat and achieve rapid quenching effect; Oil cooling is suitable for square tubes that require higher toughness, with a slower cooling rate that can enhance toughness while maintaining hardness. Hebei Forever Electromechanical’s square tube quenching treatment line provides flexible cooling options and adjusts cooling parameters according to the material and specifications of the square tube.

Regular maintenance is essential to ensure the long-term stable operation of the steel pipe induction quenching and tempering furnace . Mainly includes cleaning system: regularly cleaning the dirt and sediment in the heating and cooling system, ensuring equipment heat dissipation and heating effectiveness. Electrical system: regularly inspecting the electrical control system to ensure the normal operation of temperature control, heating and cooling equipment. Replacement of vulnerable parts: regularly inspecting the induction coil and cooling system, timely replacing worn or aging parts to extend equipment service life. Hebei Forever Electromechanical provides complete equipment maintenance manuals and technical support services to help customers maintain equipment working condition.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 01-07-2025