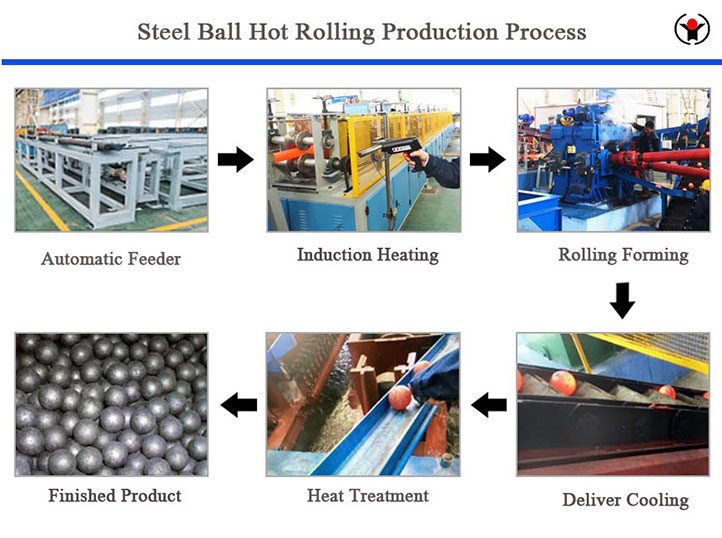

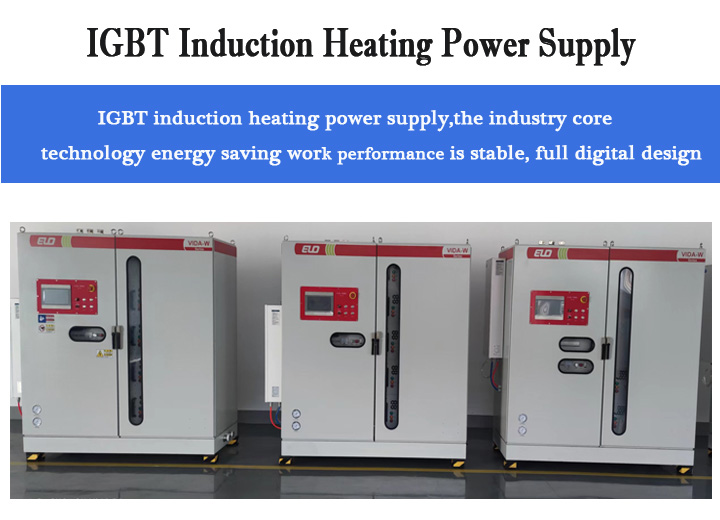

The steel ball hot rolling production line integrates intelligent temperature control and efficient forming technology, suitable for high-strength steel ball processing in mining and heavy industry fields. The steel bar enters the induction heating furnace through an automatic feeding system, and a stable power supply of 3000kW is provided. The output temperature is controlled between 950-1150 ° C. The heated steel bar enters the spiral hole roller and is accurately formed at high temperature. The formed steel ball quickly enters the rolling system for cooling, ensuring uniform hardness.

The steel ball hot rolling equipment is precisely controlled by a PLC system throughout the entire process, with a high degree of automation, suitable for industrial scenarios with strict requirements for steel ball quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-25-2024