The application fields of Forever Long bar induction heat treatment machine are extensive, mainly including the following aspects:

Automotive parts manufacturing

Steering gear and rack blanks: The Forever long steel bar heat treatment production line can perform quenching and tempering treatment on automotive steering gear and rack blanks (bar materials) to improve their hardness, toughness, and fatigue resistance, meeting the requirements of automotive components in complex working conditions.

Other shaft blanks: Various shaft blanks can also be quenched and tempered through the Foreer long steel bar heat treatment production line to improve their comprehensive mechanical properties and provide a good foundation for subsequent processing and use.

Engineering machinery field

Single pillar, suspended support, metal long beam, U-shaped steel frame π – beam, etc.: In mining machinery, these components require high strength and wear resistance. Forever long bar induction heat treatment production line can perform quenching and tempering treatment on them to improve their performance and extend their service life.

Other construction machinery components, such as bucket teeth of excavators and shovel teeth of loaders, can improve their hardness and wear resistance through heat treatment, enhancing their wear resistance in harsh working environments.

Petroleum Machinery Industry

Oil drill rods, drill collars, sucker rods, etc.: The Forever steel rod heat treatment production line can perform weld quenching and tempering heat treatment, pipe end thickening heating, welding preheating, etc. on oil drill rods to improve their strength and corrosion resistance, and meet the complex working conditions requirements in the oil extraction process.

construction industry

Prestressed steel bars: For 30MnSi material steel bars, the Forever steel bar heat treatment production line can perform a series of processing such as bending, rust removal, drawing, scoring, straightening, quenching, tempering, etc. to make its various indicators meet the requirements of GB/T5223.3-2005 pipe pile steel bars, which are used for prestressed concrete structures in construction projects.

Steel pipe processing industry

Thick walled steel pipes and stainless steel pipes: The Forever steel bar heat treatment production line can be used for heat treatment processes such as quenching and tempering, black solid fusion, and bright annealing of steel pipes to improve their performance and surface quality, meeting the requirements of different industries for the use of steel pipes.

Other areas

Steel strand and steel wire: The Forever long bar induction hardening and tempering machine can perform quenching and tempering treatment on steel strand and steel wire to improve their strength and toughness, and is widely used in fields such as bridges, construction, and power.

Workpieces with high wear resistance, such as rollers and molds, can be surface quenched using a Forever steel rod surface quenching furnace to improve their surface hardness and wear resistance, and extend their service life.

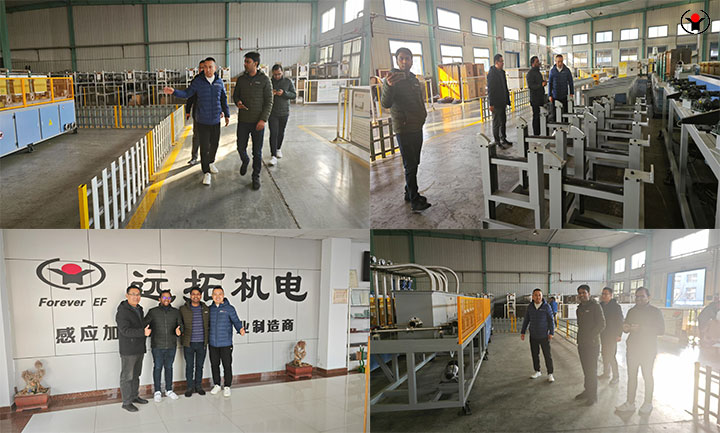

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-25-2025