The steel billet heating equipment needs regular maintenance. Why ?

Long term high load operation of steel billet heating equipment inevitably leads to problems such as component wear and performance degradation. Regular maintenance can not only reduce the failure rate of equipment, but also avoid losses caused by unexpected shutdowns. Hebei Yuantuo Electromechanical suggests that customers develop a reasonable maintenance cycle based on the frequency of equipment use.

Regular maintenance content:

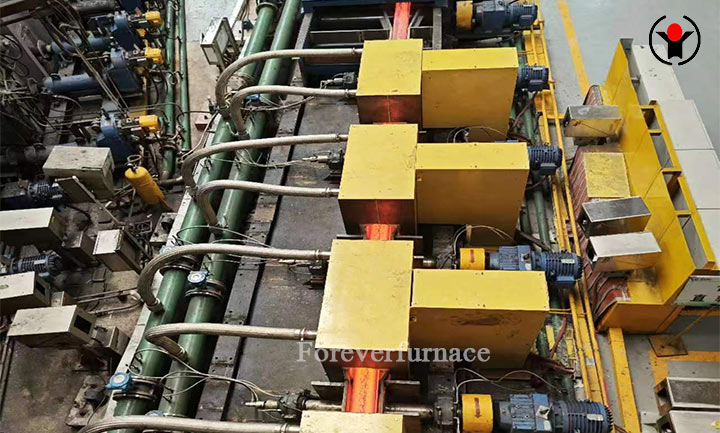

1. Heating coil inspection and cleaning:

-Check whether the coil is deformed or worn, and replace any abnormal components in a timely manner.

-Clean the surface of the coil to ensure that the electromagnetic induction efficiency is not affected.

2. Maintenance of cooling system:

-Check the flow rate and pressure of the coolant to ensure effective cooling.

-Clean the cooling pipeline to avoid blockage affecting cooling efficiency.

3. Maintenance of electronic control system:

-Test whether the performance of components inside the electrical control cabinet, such as contactors, relays, etc., is normal.

-Clean the dust in the electrical control cabinet to ensure a good heat dissipation environment.

4. Tightening and lubrication:

-Check if the bolts of each component of the equipment are loose and tighten them if necessary.

-Add lubricating oil to rotating components to avoid excessive wear and tear.

5. Running tests:

-Before operating the equipment, conduct a trial run test to observe whether there are any abnormal noises or unstable heating effects.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-24-2025