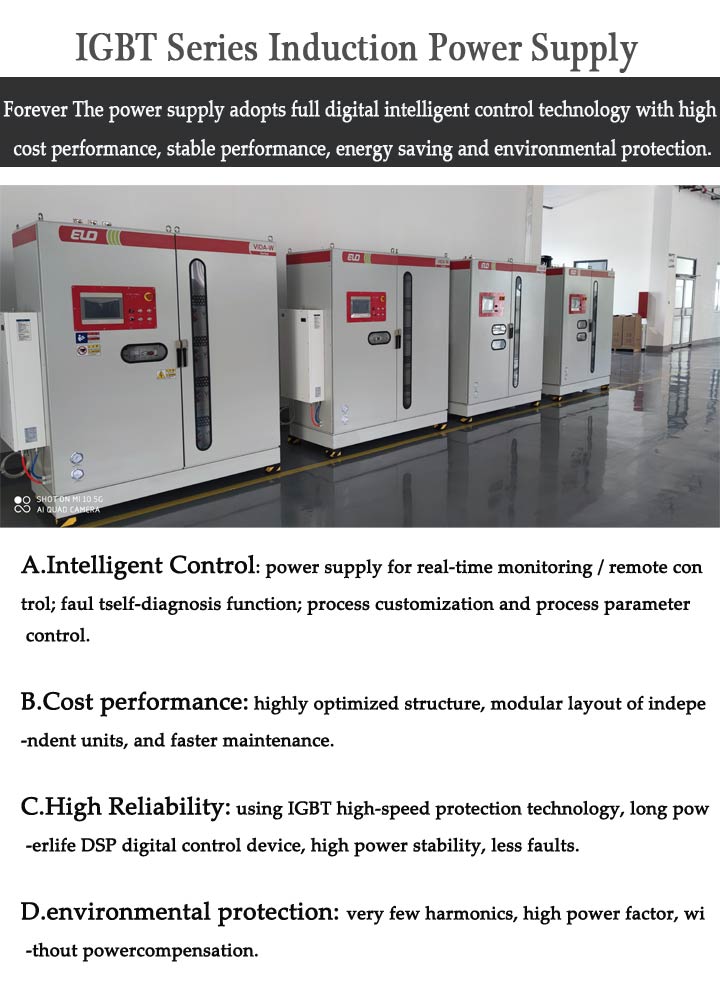

The IGBT intelligent induction heating power supply designed by Forever adopts a three loop oscillation circuit, which has high output efficiency, stable performance, and strong load adaptability. The IGBT induction power supply is 10-30% more energy-efficient than the KGPS series power supply. The microcomputer controlled voltage regulation power supply can smoothly adjust the output power and detect and display the equipment operation status at any time; The IGBT new energy-saving power supply has various protection functions and is also equipped with a one click factory reset function.

IGBT Enery-saving induction heating power is a constant power output power supply that can achieve full power output even with a small amount of material, and always remains unchanged. It heats workpieces quickly and has high production efficiency; Due to the use of series resonance in the inverter section and the high inverter voltage, all IGBT intermediate frequency devices are more energy-efficient than ordinary thyristor intermediate frequency devices; IGBT intermediate frequency adopts frequency modulation and power regulation, and the rectification part adopts full bridge rectification, with inductance and capacitance filtering. GBT intermediate frequency produces small high-order harmonic components and has low pollution to the power grid.

High order harmonic interference: High order harmonics mainly come from the burr voltage generated by the thyristor during voltage regulation in the rectification part, which can seriously pollute the power grid and cause other equipment to malfunction. The rectification part of the Energy-efficient electric heating power supply adopts a semi controllable rectification method, and the DC voltage always works at a high level without adjusting the conduction angle. Therefore, it will not generate high order harmonics, pollute the power grid and transformers, and the switch will not generate heat, which will not interfere with the operation of other electronic devices.

The induction coil designed by Forever has space between turns, which can improve the efficiency of coil current carrying and make the water vapor in the furnace lining material easily evaporate. A common problem with induction heating equipment in a gapless induction coil furnace is that the coil is often affected by the magnetic field of adjacent lines, resulting in an increase in impedance.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-14-2025