The long bar induction heat treatment furnace consists of power supply equipment, quenching device, conveying device, sensor, PLC control system, cooling circulating water system, and conveying device. Place the 45 steel rod into the heating area of the induction furnace, ensuring that there is an appropriate distance between the rod and the furnace wall to avoid thermal damage caused by contact with the furnace wall. Open the control panel of the induction furnace, set parameters such as heating temperature and heating time, and then press the heating button to start the heating process.

During the heating process, closely monitor the changes in furnace temperature to ensure that the temperature is controlled within the required range. When the bar reaches the preset temperature, maintain it for a period of time (insulation) to ensure uniform heating of the bar. After the insulation is completed, the rod material is taken out of the furnace and quickly cooled, which can be achieved by air cooling or water cooling.

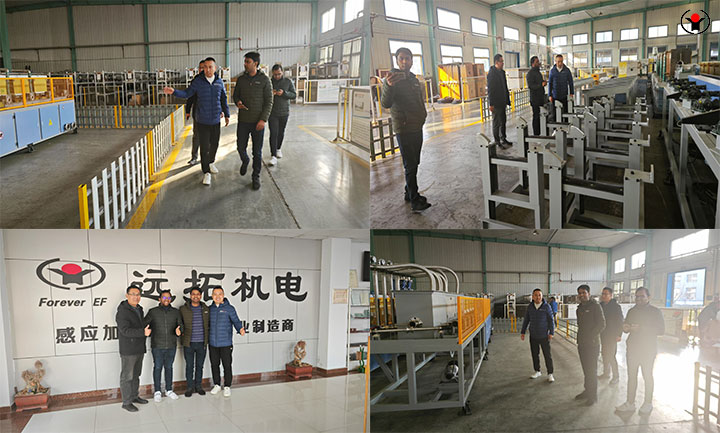

Hebei Forever Electromechanical has always been committed to providing customers with high-quality and efficient stamping equipment and solutions. Through Forever Electromechanical’s 45 long bar induction hardening and tempering fruance , bar material heat treatment manufacturers can achieve rapid and large-scale steel production, and improve production efficiency and product quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-19-2024