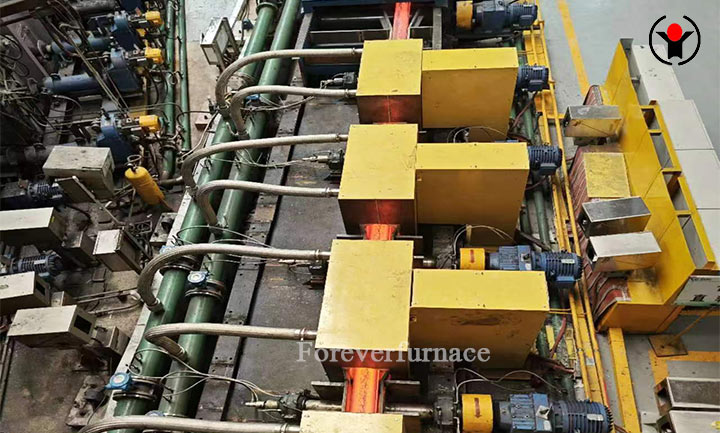

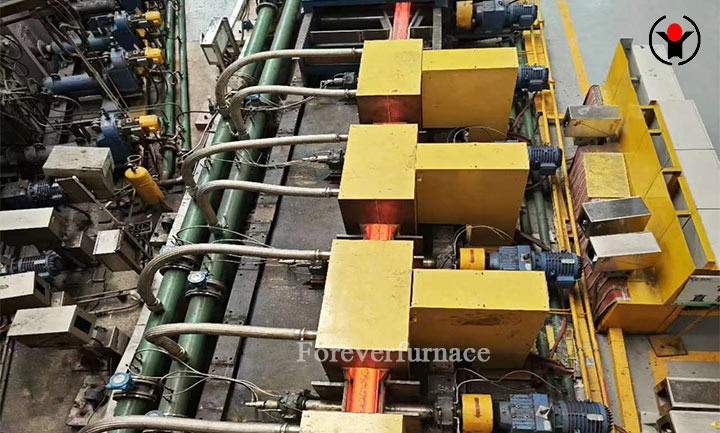

Continuous casting billet induction heating furnace

Features:

Product Detail

Application Video

Product Tags

The continuous casting billet reheating furnace adopts PLC control characteristics:

·Provide remote control consoles with touch screens or industrial computer systems according to user needs. Specially customized human-machine interface, highly user-friendly operation instructions, allowing one person to operate the entire equipment, saving labor and costs. All digital, high depth adjustable parameters, as long as the steel type, size, and equipment of the workpiece are input, the relevant parameters will be automatically called up without manual recording, reference, or input. Has high-precision historical curve function. It can be backed up via USB or network, and data can be saved for a long time. (If there is a problem during adjustment or if you want to restore the device to its original state, simply follow a strict level management system, and the device is equipped with a one click restore system. A button can restore the original data)

Parameters and characteristics of the Continuous casting billet heating furnace provided to users:

★ Steel type and material: carbon steel, alloy steel;

★ Steel billet size: 120mmx120mmx6000mm;

*Large curvature of steel billet before entering the furnace: 1000mm, large curvature ≤ 4mm

★ Surface temperature before entering the furnace: 2850 ℃ C

*Control system: The entire heating process is automatically controlled by PLC, and production records such as heating quantity are displayed in a timely manner. This console is designed for standalone use, with a specially customized human-machine interface, highly user-friendly operation instructions, fully digital and deep adjustable parameters, and a one click restore function. It is easy to operate.

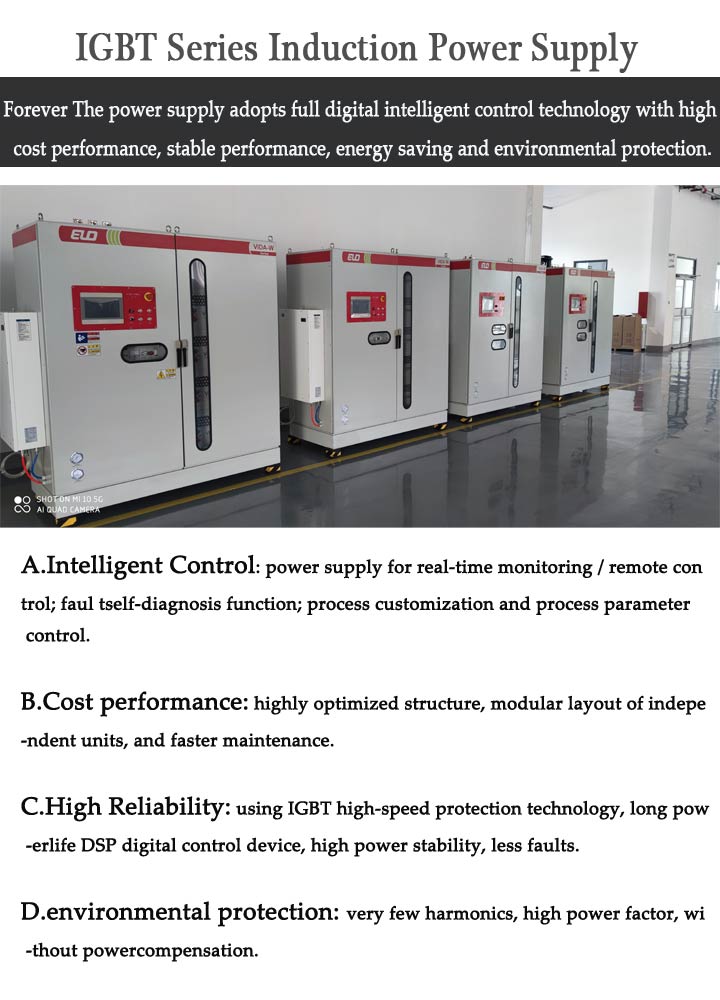

★ Power supply requirements: Dual power transformers, 12 pulse rectifier power supply, can infinitely reduce harmonic pollution and improve work efficiency

★ Feeding and guidance system: Each axis is driven by an independent motor reducer, with multi axis drive and single frequency converter control to synchronize multi axis operation. The components are selected from well-known brands, with reliable quality and stable operation. Using 304 non-magnetic stainless steel guide wheels, the axial elasticity of the guide wheels is maintained to adapt to bending within the allowable range of steel failure. All cabinets are sandblasted, sprayed with plastic, and baked with paint. The waterways are made of thick walled stainless steel. The continuous casting billet reheating furnace is corrosion-resistant and has a long service life. The equipment is equipped with a large LCD temperature display screen (which is convenient for on-site personnel to observe and display data).

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.