Drill rod heat treatment machine

Features:

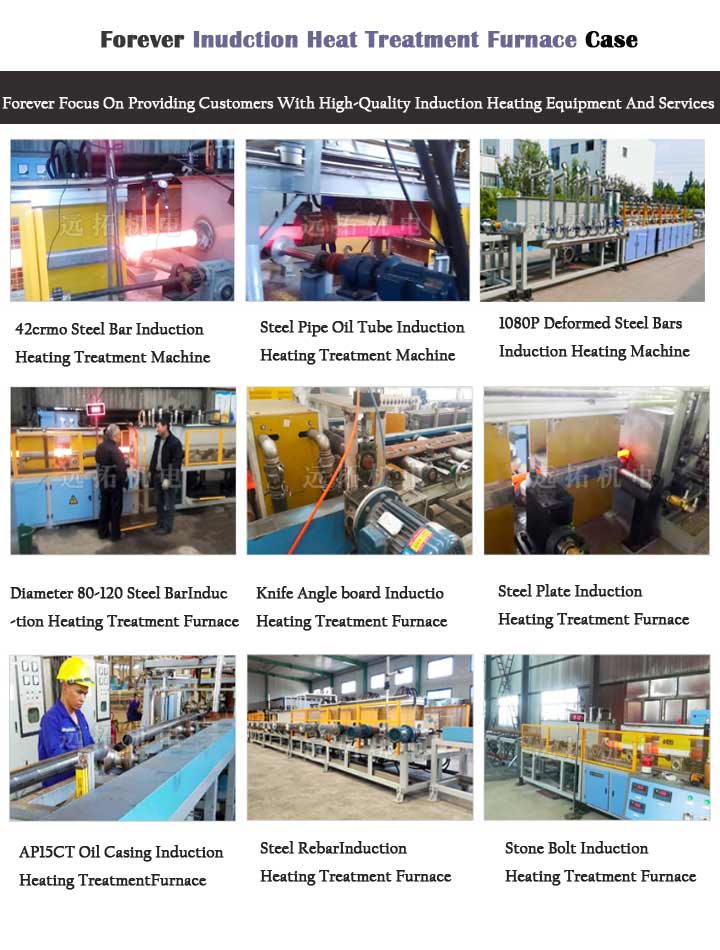

● Application: Heat treatment line for drill pipes, tubing, casing, drill rod

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

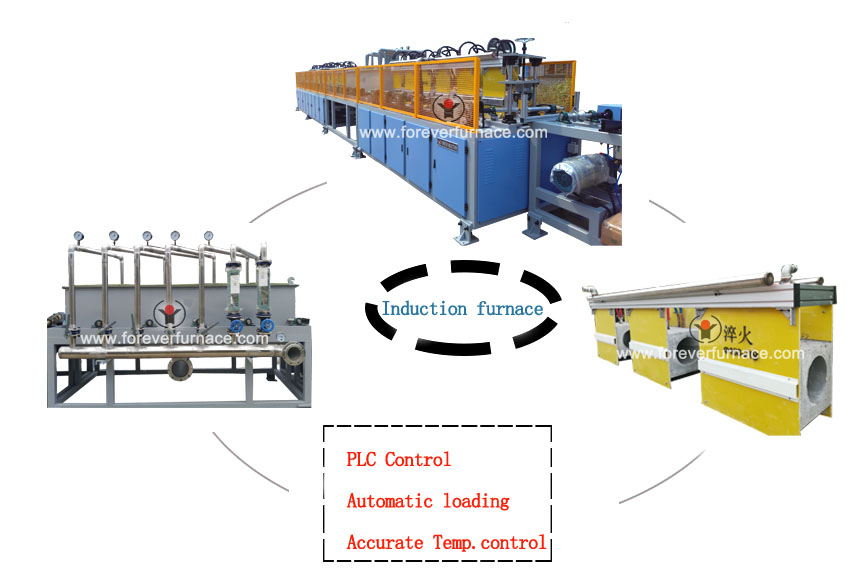

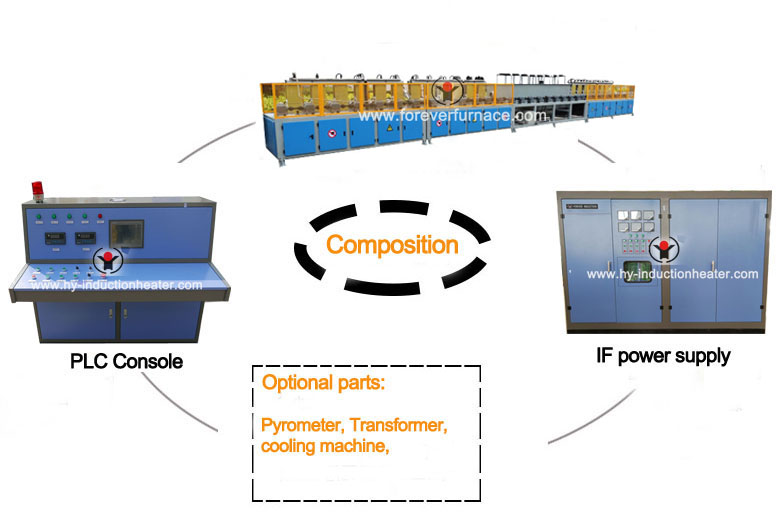

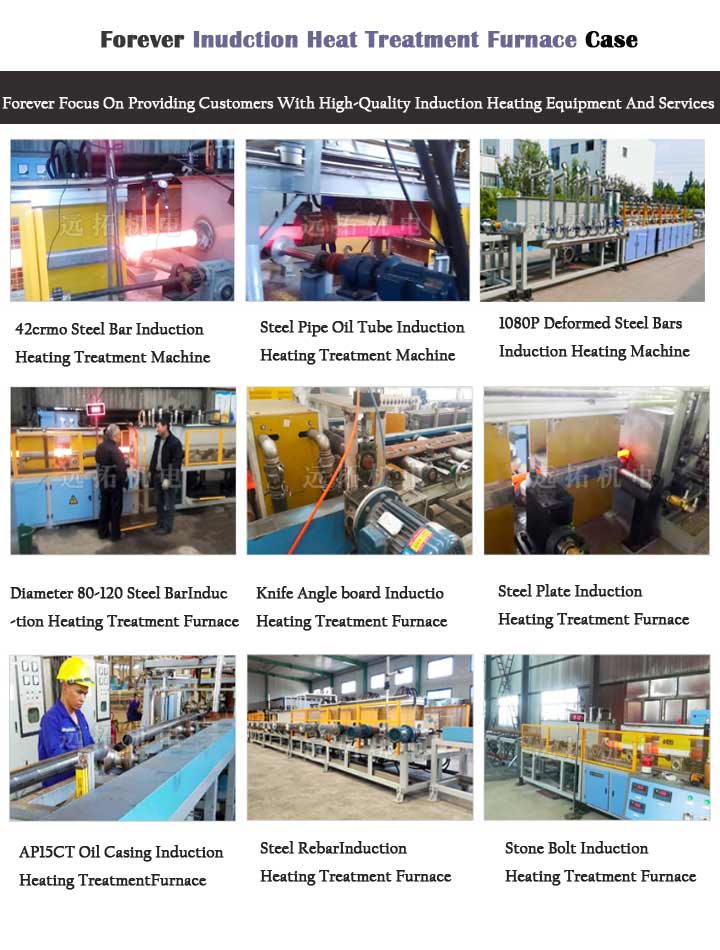

Nowadays, the drill rod heat treatment machine with induction heating has replaced the traditional gas heating furnace and trolley heating furnace, and is suitable for induction heat treatment of different workpieces. The drill rod heat treatment machine adopts PLC control system, simple operation and can realize automatic conveying, heating, water cooling, high temperature tempering, automatic unloading and other functions.

Induction heating drill rod heat treatment machine technical parameters:

Induction heating drill rod heat treatment machine technical parameters:

● Equipment name: drill rod induction heat treatment equipment

● Equipment brand: Forever

● Workpiece material: carbon steel alloy steel

● Diameter: 20-300mm

● Length range: 2-20m

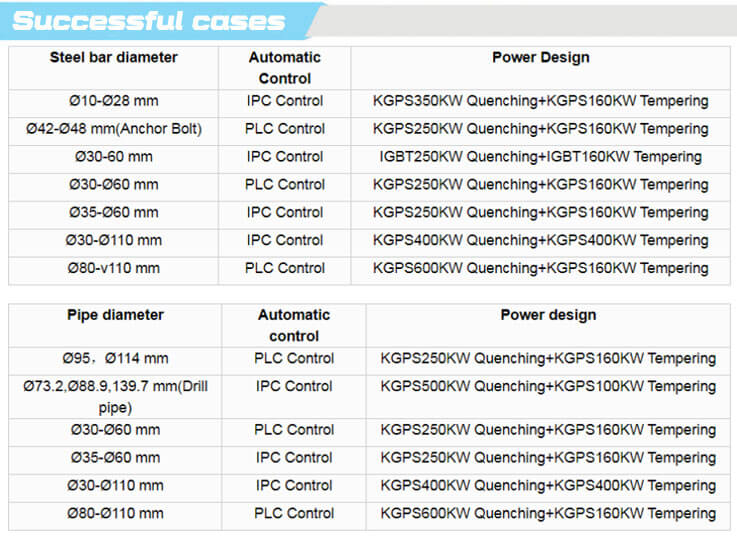

● Medium frequency power supply requirements: 100KW-8000KW

● Closed loop temperature control: Automatically adjust

● Quality standard range: yield strength, tensile strength, hardness and impact performance can meet the national standards.

The advantages of drill rod heat treatment machine are:

● The resonant medium frequency induction heating power supply specially designed by Forever is more energy-saving and efficient than the ordinary power supply.

● The angle between the roller shaft and the workpiece is 18-21°. The drill rod rotates at a uniform speed and moves forward at a uniform speed. The furnace roller is 304 non-magnetic stainless steel and water cooled.

● The uniform cooling of drill rod heat treatment machine can meet the requirements of different workpiece hardenability. The quenching system adopts multi-stage spray cooling, and the pressure and flow of spray ring can be adjusted.

● The workpiece will be placed in the spray ring to ensure uniform pressure and flow, so the rod does not need to be straightened after quenching and heat treatment. The surface hardness difference is very small.

● Closed-loop temperature control system for induction hardening and tempering equipment: Forever has professional engineers to set process parameters for the system. When the heating temperature is too high or too low, the system will adjust the temperature to the required temperature and reach the required temperature by adjusting the power.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !