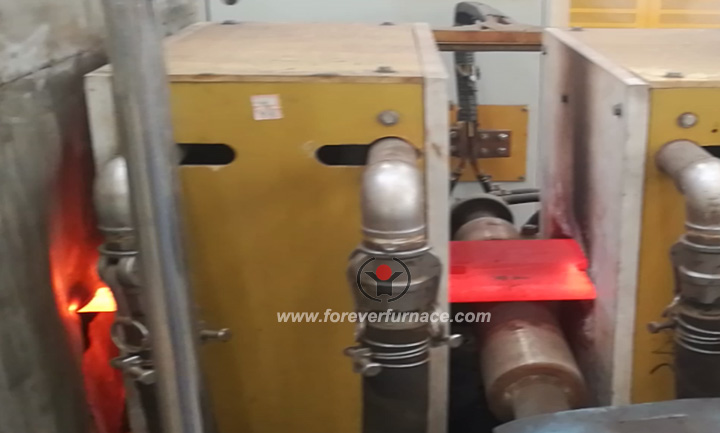

steel plate induction hardening machine

Features:

| Application | Heat treatment for steel bar, steel pipe, steel billet, shaft, drill rod |

| Power | 100 KW-10000 KW |

| Non standard |

Professional Customization |

Product Detail

Application Video

Product Tags

Product Name: steel plate induction hardening furnace

Typical Application:Used for workpiece quenching, tempering, annealing, normalizing etc.

Workpiece available: Solid bars, rods, pipes, tubes, plate, sheet, square pipes, sucker rod, grinding rod etc.

Working mode: Automatic & manual

Inverter: Solid power supply cabinet

Heating way: Induction heating for the workpiece

Parameter record: PLC automatically record

Quality warranty period: 12 months

Inducution plate hardening furnace characteristics

● The steel diameter can be up to 7.000 inch(177.80 mm), improving the production capacity of the plant.

● Advanced quenching and tempering technology with continuous rotation can realize maximum uniformity of steel.

● Customized design and production according to customer’s requirement.

● Precious, fast and uniform heating can realize output maximization and quenching optimization.

● The maximum degree of extension of bar and pipe can be achieved due to the cancellation of the cold correction and stress relief process.

● Based on the higher rotation speed and optimized quenching mode, the outer diameter deformation of the steel can be reduced greatly.

steel plate heat treatment furnace usage

● Continuous diathermy for long bar material such as sucker rod;

● Step heating for round or square short bars;

● Surface hardening for steel pipe, shaft,axle and gear;

● Multi station partial heating.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.