Medium frequency induction heating power supply

Features:

The control system adopts a human-machine interface, highly user-friendly operation instructions, and provides touch sensitive features

Remote control console for touch screen industrial computer system, fully digital high depth adjustable parameters

Make your device control more effortless

One click restore, multiple language switching.

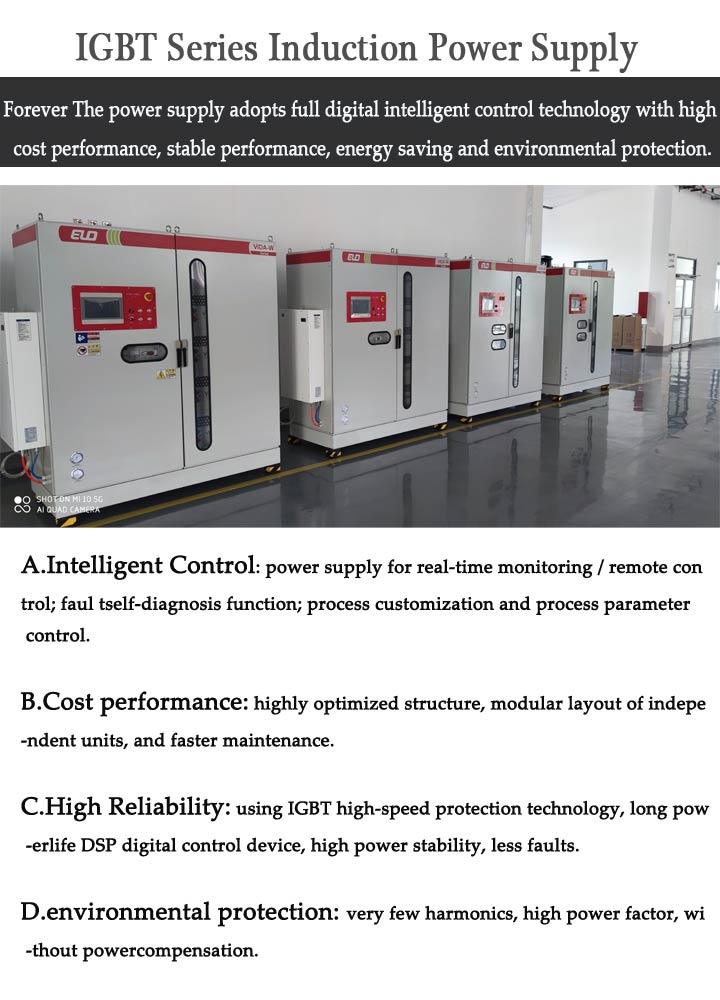

Product Detail

Application Video

Product Tags

Characteristics of Medium frequency induction heating power supply :

20KHz broadband adaptive: One power supply is suitable for multiple loads, and there is no need for professional personnel to debug when changing loads. It can achieve frequency adaptation from intermediate frequency to ultrasonic frequency answer.

Constant power output mode: The output power does not change with the temperature of the workpiece, resulting in high production efficiency and good product quality.

The medium frequency induction heating power supply has a high success rate of startup and can switch between constant power/constant voltage output modes freely. It has good resistance to voltage fluctuations: when the voltage fluctuation range is between 360-410V, it does not affect product quality. High reliability/low failure rate: the overall structure and circuit design of the power supply are synchronized with international standards, a comprehensive intelligent protection system is used, international brand components are selected, and the signal is transmitted through optical fiber to avoid interference

High performance DSP processor: Real time monitoring and fast processing to ensure output accuracy.

QIS Quality Monitoring System and Quality Traceability Function: The powerful storage function can store production batch numbers, employee numbers, operation events, status events, and so on

The intelligent fault diagnosis and online display fault handling method for intermediate frequency induction heating power supply can quickly identify the cause and accountability of quality problems, such as faults. Most faults can be solved by operators, improving production efficiency. The operation status monitoring system accurately, comprehensively, and comprehensively displays the power supply operation status, making it easy to formulate and modify processing technology. The parameters of the Intelligent induction heating power supply can be set online or remotely, and the parameters set after power failure are not lost.

Powerful communication function: Reserved RS485/232 interface can exchange data with external controllers (industrial computers, industrial touch screens, laptops, etc.) or central control rooms.