Round Steel Continuous Heating Equipment

Features:

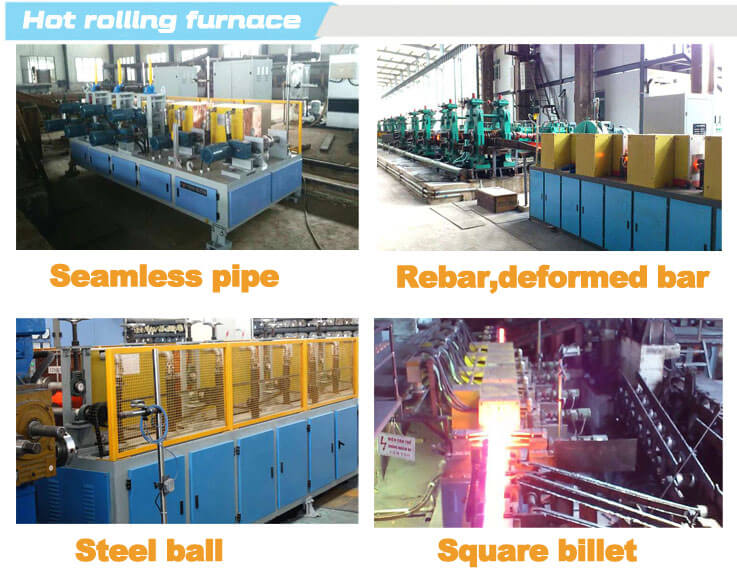

1.Application:Heat Treatment for Round Steel,Steel Bar,Steel Pipe,Oil Steel Pipe,

2.Available Power:100KW-10000 KW

3.Non-standard Product;Professional Customization

Product Detail

Application Video

Product Tags

We are one of the leading manufacturers of round steel continuous heating equipment in China, dedicated in researching energy-saving technology for medium frequency induction heating power supply for more than 20 years.

Especially our large power induction heating furnace has been proven successful at Taiwan and Vietnam(Up to 7500KW), which is equipped with with PLC automatic control for the production process,which saves labor cost and improves working efficiency.Forever Furnace can provide the most energy-efficient solutions and equipment according to your material processing requirements.

Round Steel Induction Heating Equipment for rebar rolling working at Kun Steel Group

1.Advantages for Round Steel Continuous Heating Equipment

(1)High induction heating efficiency.The induction heating efficiency can be up to 70%.

(2)Improve the labors working environment greatly.With electromagnetic induction heating principle,there is almost no dust,exhaust gas or heat loss.

(3)Fast heating speed.You needn’t preheat the equipment like other machine,so your material can be heated rapidly.And the oxidization burning loss rate of the bloom is only 0.5%-1%.

(4)Fast heating speed can improve production efficiency greatly.It can work with other equipment in the production line.

2.Three Attentions for Users to Choose Round Steel Continuous Heating Equipment:

(1)Equipment Power:

Usually,larger power for induction heating equipment means it can heat bigger size and heavier material.

(2)Equipment Frequency:

Usually,larger frequency for induction heating equipment means it has faster surface heating speed,and it can heat smaller work piece.So high frequency induction heating equipment is mainly used for welding or surface hardening heat treatment.

Lower frequency for induction heating equipment means it can heat the work piece uniformly when the work piece is thick.So medium frequency induction heating equipment is mainly used for hot forging or depth hardening heat treatment.

(3)Induction Coil:

Sometimes the power and frequency for the induction heating equipment can meet the heating requirement,but the calculated power and frequency is not suitable to work as the work piece shape is special.In this condition,you should order special induction coil and get the best power and frequency through testing method.

As a professional manufacturer of induction heating equipment,Forever Furnace can provide the superior heat treatment system with the most reasonable price as per 20 years experience.Forever Furnace will make you be more competitive!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.