Seamless pipe induction heat treatment machine

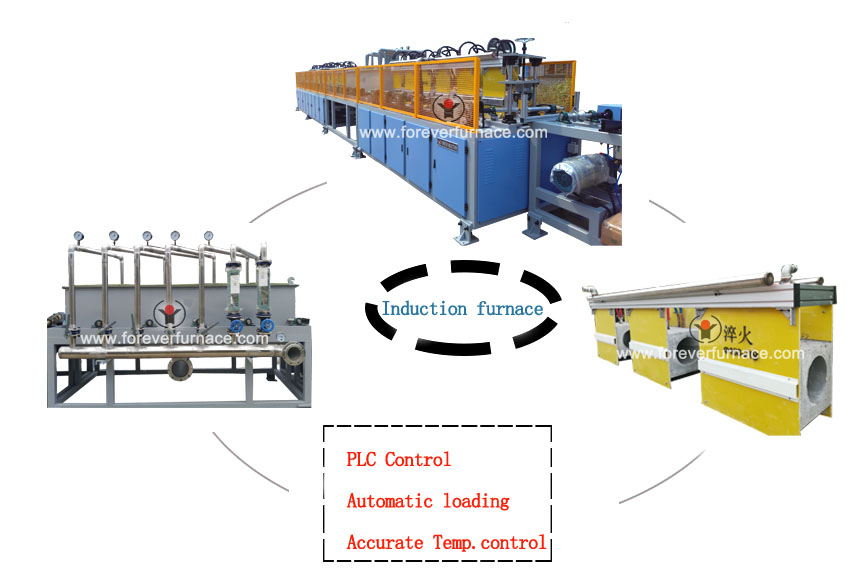

Features:

● Application: Heat treatment line for drill pipes, tubing, casing, OCTG

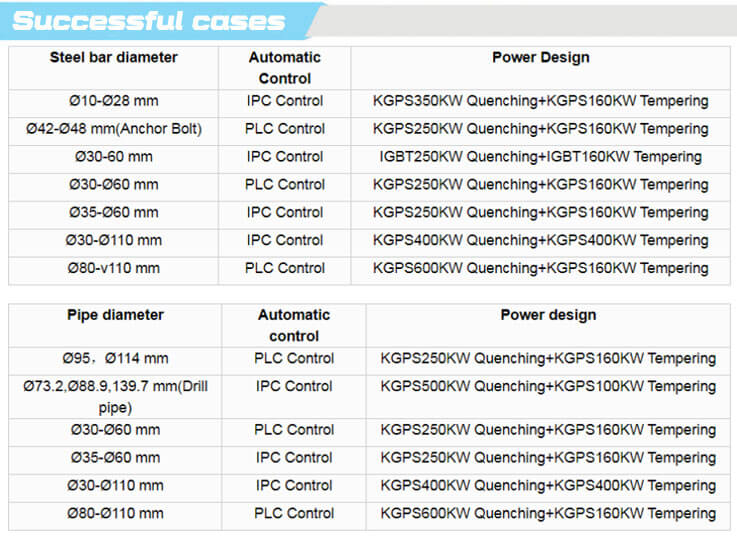

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

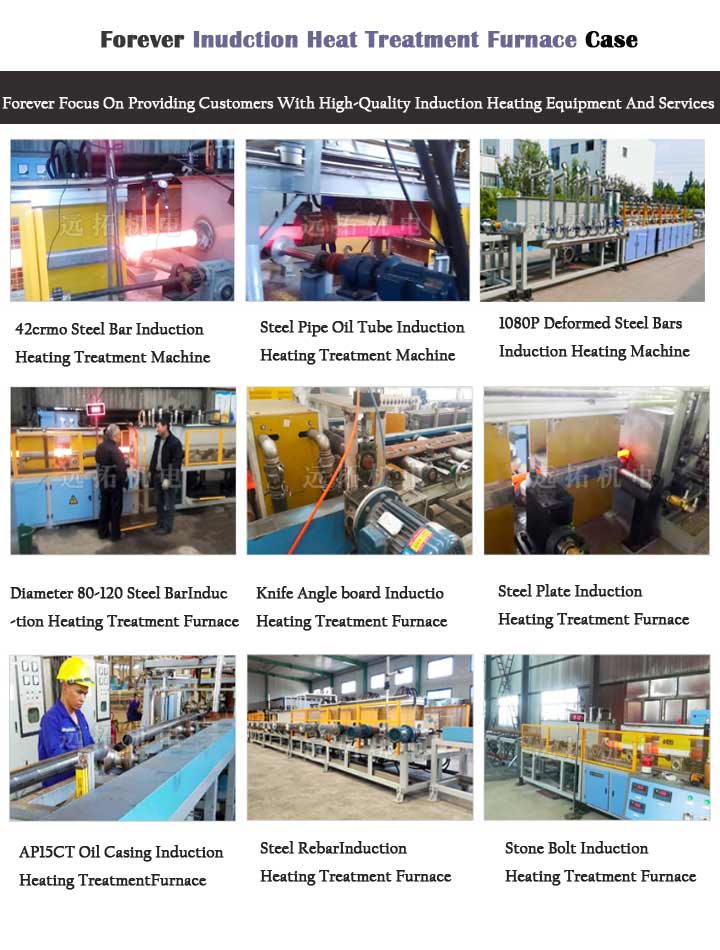

In 2017, Forever company introduced advanced induction heat treatment equipment technology, the seamless pipe heat treatment machine adopts advanced industrial control computer to control the whole system, the seamless pipe heat treatment machine has high reliability, high load continuous 24 hours of work.The seamless pipe heat treatment machine has protection functions of over-voltage, over-current, water shortage, load short circuit.

Technical parameters of seamless pipe heat treatment machine:

● Name of equipment: seamless pipe heat treatment machine (non-standard products)

● Equipment brand: Forever

● Steel material: SPCC, IF, DC06, 201, 304 and other materials.

● Size: workpiece with thickness greater than 2.0 mm

● Production efficiency requirements: as per user’s need

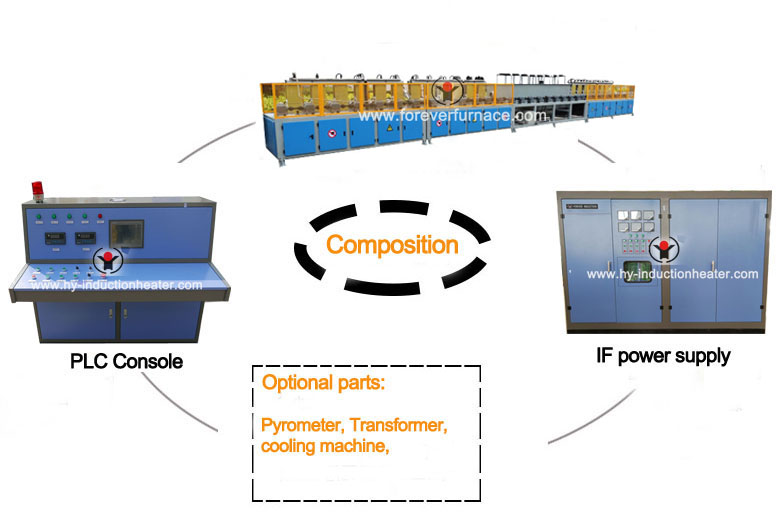

● Device power range: KGPS100KW-500KW

The seamless pipe heat treatment machine is characterized by PLC control.

● Provide remote operation cabinet with touch screen or IPC based on user needs.

● Customized man-machine interface, highly humanized operation instructions, one person can operate a whole set of seamless pipe heat treatment machine, saving labor and costs.

● All digital, high depth adjustable parameters, as long as you input the workpiece steel, size, the equipment will automatically call the relevant parameters, do not need to manually record, consult, input. It has the function of high precision historical curve. U disk or network backup, data can be preserved for a long time.

● Strict grade management system. The seamless pipe heat treatment machine is equipped with one key restoring system.

At present, most manufacturers in China manually adjust and test different parameters of seamless pipes parameters manually. Forever engineer develops full automatic intelligent control system and can help users to test and get proper parameters database.

Therefore, the operation of this system only needs simple training for the operator, and does not require special professional skills. Moreover, programmed operation ensures consistency of product quality compared with manual adjustment. Choosing Forever seamless pipe heat treatment machine is equivalent to saving a lot of cost and labor for you.

Configuration and performance of mechanical parts of seamless pipe heat treatment machine

1. Roller table + power double pressure rollers, each shaft driven by an independent motor reducer, independent frequency converter control, so that the steel pipe can move flexibly and uniformly on the roller table.

2. The frame of the conveying mechanism has enough strength and stiffness. In order to make the installation of the equipment easy, the adjustable foot is installed at the bottom of the frame to make the whole equipment more beautiful.

3. According to the safety and standardization requirements of the mechanical industry, all the exposed parts of the rotating machinery are equipped with reliable protective covers.

4. The heat treatment production line of seamless pipe quenching and tempering is energy-saving and efficient, and the heating is uniform.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

heat treatment machineWelcome your inquiry for quenching and tempering induction heat treatment equipment !