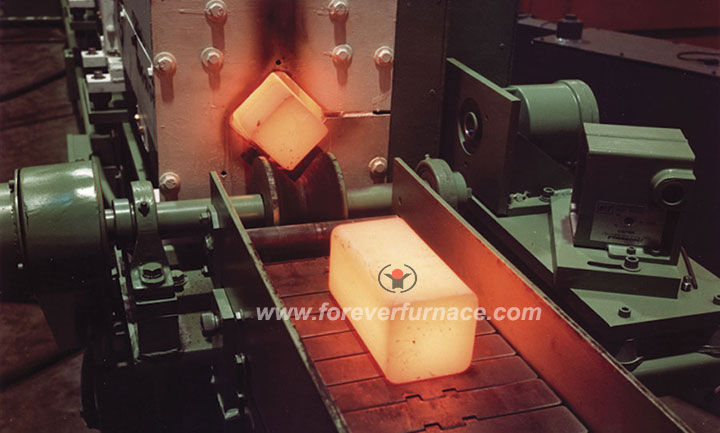

Steel billet heat treatment production line

Features:

| Application | Steel billet heating, rolling,forging,shearing |

| Power | 100KW-10000KW |

| Non-standard |

Professional Customization |

Product Detail

Application Video

Product Tags

Product Name:Steel billet heat treatment production line

Steel billet heat treatment furnace

Typical Application:

Forever steel billet heat treatment production line is specialized designed and produced for our Taiwan customer. Whole heating process control : Siemens PLC automatic control system; record all the production data automatically.

Process requirement for steel billet heat treatment production line

● Billet size: φ 175× 600mm, φ 155× 600mm

● Heating temperature: 1200 -1250 ℃

● Production capacity: 30S/piece

● Incoming line voltage: 1000V

Steel billet heat treatment production line configuration

● 2000 kW/400Hz Inverter

● Billet induction heating furnace

● Automatic feeding device

● Conveyor roller

● Discharging separator

● PLC console

● Medium frequency power supply

The main features of steel billet heat treatment production line are as follows:

1. During the heating process, the steel billet heat treatment production line will not generate sparking. It will run reliably and steadily.

2. Full digital control and SCR’s unique temperature patrol device is intuitive and convenient.

3.Low power consumption, good economy, long operation and low cost.

4. The whole set of steel billet heat treatment production line can be designed as a full closed form, which is not only beautiful but also greatly improved in safety; the realization of various protective measures provides a reliable guarantee for the safe operation of the equipment.

5. Mature design and continuous improvement make the failure rate of steel billet heat treatment production line almost zero.

We usually make the steel billet heat treatment production line as per users’ specific requirements.So please tell us the size,length and heating temperature of your steel billet, then we will give you the best Induction heat treatment machine solutions suitable for your plant.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.