Steel pipe induction annealing furnace

Features:

Features:

Brand: Forever Electromechanical

Diameter: 20-150 mm

Length: 2-20m

Material: Carbon steel alloy steel

Power requirements: 80-5000 kW

Product Detail

Application Video

Product Tags

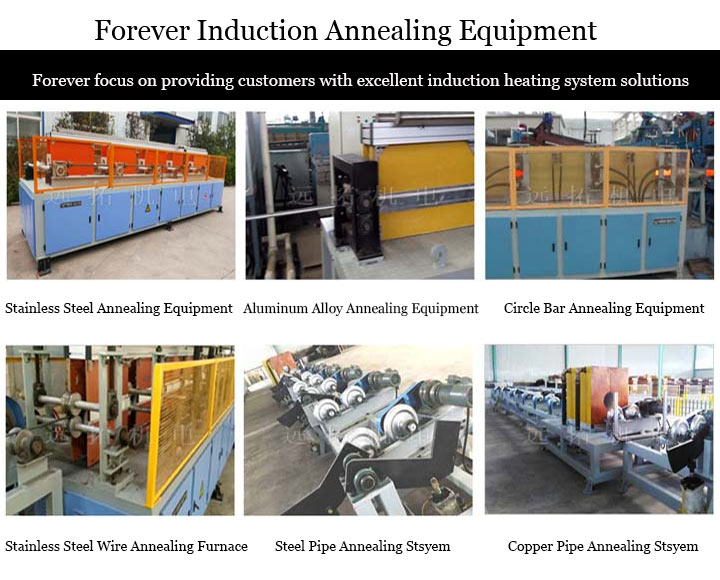

Forever has rich experience and practice in the design, process, manufacturing, and management of steel pipe heat treatment annealing equipment. Proficient in the connotation of induction heating, the perfect combination of technology and equipment. We have independent intellectual property rights in the core technology of steel pipe heat treatment annealing equipment. Modern office, high-quality talents, welcome friends from all walks of life to visit and negotiate steel pipe heat treatment annealing equipment business!

Features:

Brand: Forever Electromechanical

Diameter: 20-150 mm

Length: 2-20m

Material: Carbon steel alloy steel

Power requirements: 80-5000 kW

Quality standards: After heat treatment by this equipment, the yield strength, tensile strength, hardness, elongation, and impact performance of the steel pipe can all meet the standards.

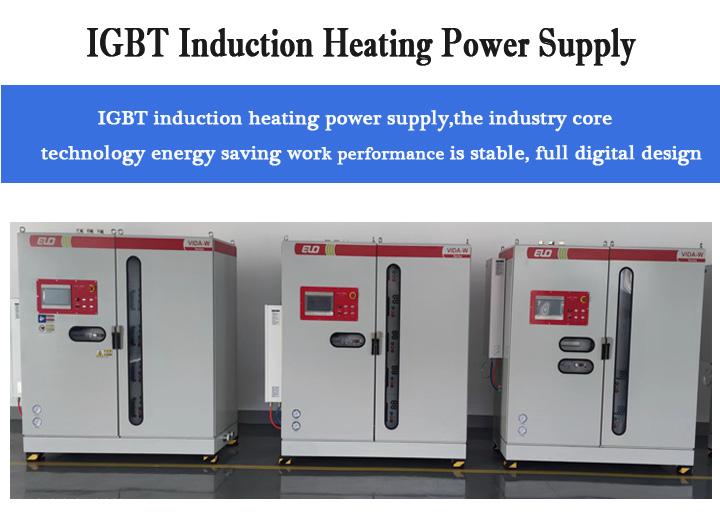

The control of the Steel pipe induction annealing furnace adopts high-performance embedded integrated chemical control computer centralized control, which has high control accuracy, stable operation, anti-interference, pollution resistance, strong vibration resistance, and simple and convenient operation. The control system for steel pipe heat treatment annealing equipment is composed of Siemens PLC from Germany, Kunlun Tongshi Industrial Control Computer from Beijing, and Leitai Temperature Measurement System from the United States, which can achieve comprehensive management of the system, achieve equipment automation, self adjustment of the system, and high production efficiency. The induction heating system adopts PLC centralized control, which can be manually or automatically controlled. The control system is reasonable, stable, reliable, accurate, and has strong signal anti-interference ability. At the same time, the system adopts an expansion module to collect temperature as a closed-loop feedback signal, which is processed by PLC program and adjusted accordingly to achieve closed-loop control of the system.

The conveying roller of the steel pipe annealing furnace forms an angle of 18-21 ° between the roller axis and the workpiece axis (designed according to different workpieces). The steel pipe moves forward at a uniform speed while self transmitting, heating uniformly. The roller is made of 304 stainless steel. The induction heat treatment equipment for steel pipes has the characteristic of long service life.