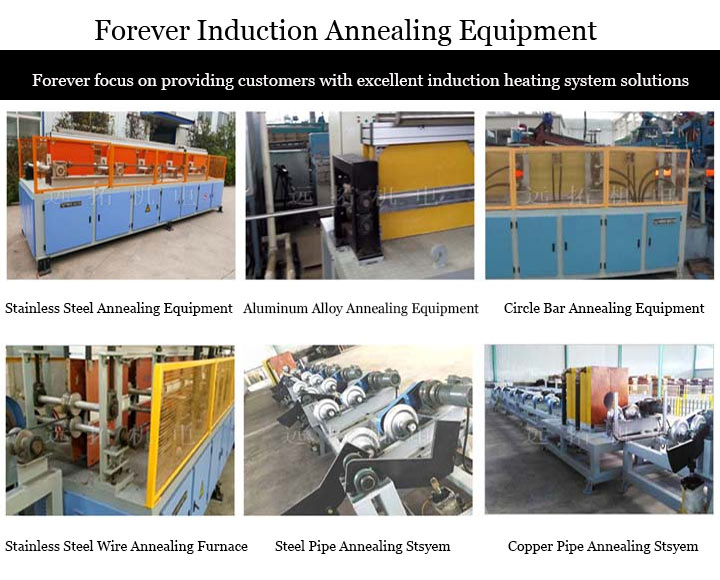

Steel pipe welds induction annealing equipment

Features:

File names: Q195, Q235, 10, 20, 35, 45, 304316, 20cr, 40cr, 20cmd, 35crmo, 42cimd, 40crnimo, GCr15, 65 im, 50mm, 50cr, 3cr2w8v, 20crhmti, 5crhmo

File Name: Diameter 10mm~406mm

work

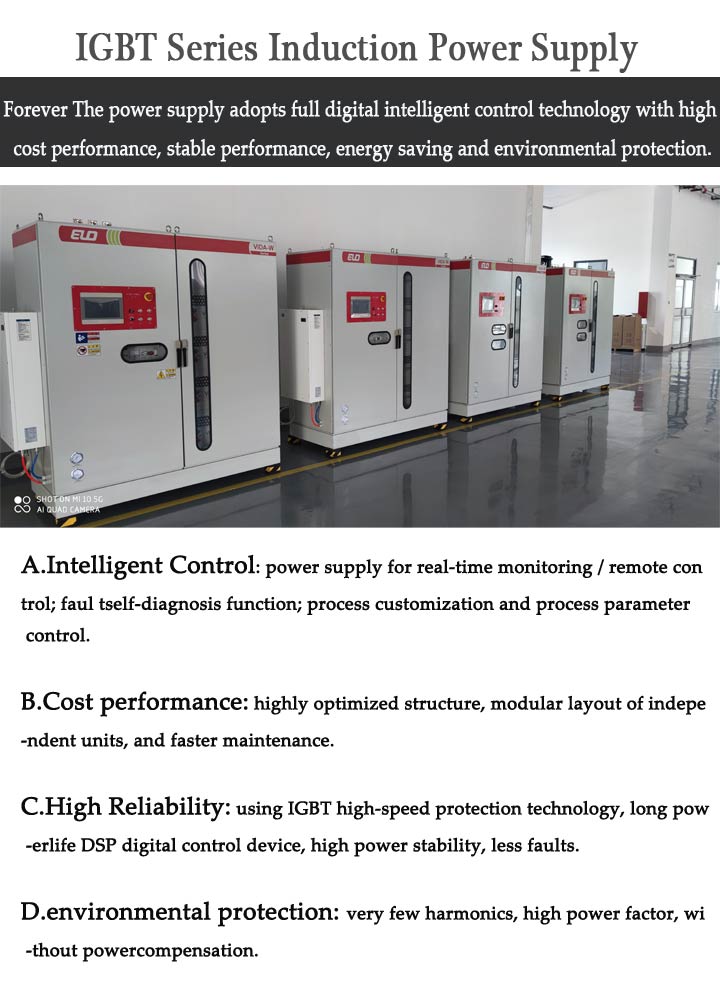

Power supply: KGPS160KW-8000KW

Work experience: Customer profile

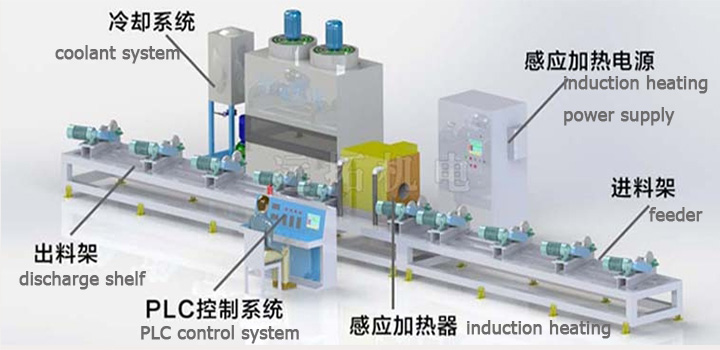

Product Detail

Application Video

Product Tags

steel pipe welds induction annealing furnace

Product Name: Steel Pipe Weld Annealing Equipment Materials: Q195, Q235, 10, 20, 35, 45, 304316, 20Cx, 40Cr, 20CKIO, 35CTIO, 42CIIO, 40CINIMO, GCr15, 65 Hm, 50Mm.50Cr, 3Cr2w8v, 20CrhmTi, 5CrhmMo, etc.

Workpiece diameter range: diameter 10mm~406mm

Workpiece length range: greater than 2m

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Power consumption: calculated based on the customer’s workpiece material and diameter, heating temperature, operating speed, etc.

The Steel pipe welds induction annealing equipment is controlled by a controllable silicon intermediate frequency power supply, with fully digital operation, reliable hardware and software protection, and complete functions. The load of the steel pipe weld annealing induction heating equipment consists of an induction line and a compensating capacitor, connected into a parallel resonant circuit. The basic working principle of a thyristor induction heating power supply is to use a three-phase bridge rectifier circuit to rectify the AC current into DC, which is filtered by a DC reactor and then converted into single-phase intermediate frequency AC by an inverter to supply the load. Therefore, this inverter is actually an AC-DC-AC converter. Energy saving and low power consumption.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.