Threaded rod induction hardening and tempering machine

Features:

【 Quenching power supply 】 160-1000KW/1-4KHz

【 Tempering power supply 】 100-600KW/1-4KHz

【 Production capacity】: 0.5-3.5 tons/hour

【 Scope of application】 Workpiece diameter ranging from 20 to 50mm; Workpiece length: 6m-15m

Product Detail

Application Video

Product Tags

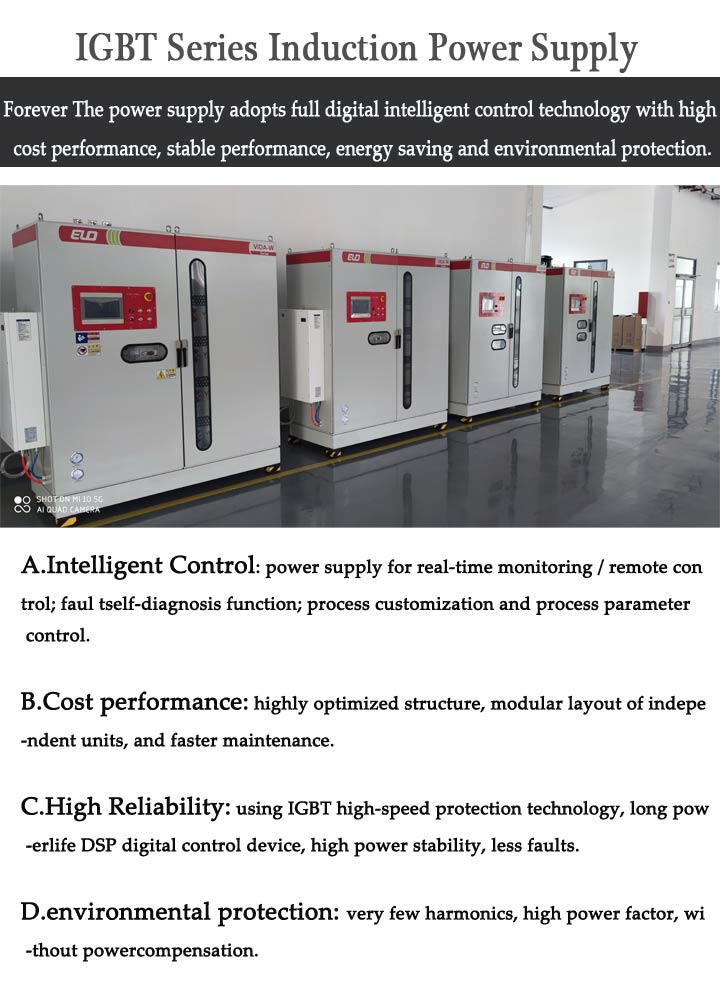

The Threaded rod induction hardening and tempering machine designed by our company is fully controlled by PLC program. Our threaded rod heat treatment furnace has the advantages of safety, energy saving, high automation, stable product quality, high production efficiency, and simple operation.

【 Quenching power supply 】 160-1000KW/1-4KHz

【 Tempering power supply 】 100-600KW/1-4KHz

【 Production capacity】: 0.5-3.5 tons/hour

【 Scope of application】 Workpiece diameter ranging from 20 to 50mm; Workpiece length: 6m-15m

【 Energy Conversion 】 Adopting quenching+tempering method, with a power consumption of 420-480 kWh per ton

The heat treatment furnace for threaded steel is mainly used to produce high-strength precision rolled threaded steel, that is, through quenching and tempering heat treatment, the various properties of precision rolled threaded steel are made to meet the requirements of PSB930 and PSB1080 levels in the national standard GB/T20065-2006.

The threaded bar heat treatment furnace is developed and produced by Hebei Forever Electromechanical Factory by combining advanced foreign technology with domestic induction heat treatment needs. It can be used for the heat treatment process of workpieces such as steel bars, rebar, and PC steel bars with diameters of 5-60mm. Forever Electromechanical Manufacturer is highly trusted by customers for its advanced technology, excellent quality of rebar heat treatment furnaces, and comprehensive after-sales service.

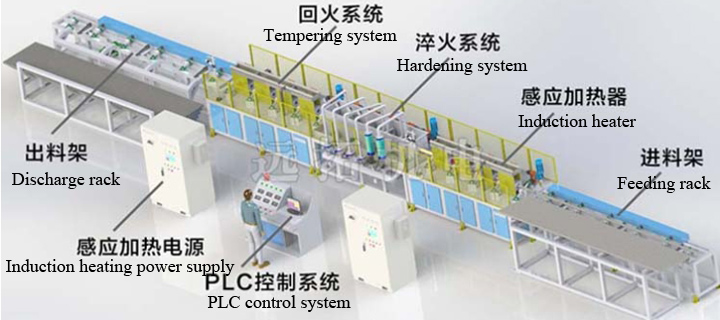

The heat treatment furnace for threaded rod includes:

Induction heating power supply, PLC intelligent control system, induction heating system, quenching system, tempering insulation system, feeding rack (feeding rack, discharging rack), and can also be customized according to customers’ actual needs: cooling system, infrared measurement system, power transformer, etc.

Characteristics of rebar quenching and tempering heat treatment equipment:

1. Adopting CNC technology, it has quenching functions such as connection, simultaneous connection, segmented connection, and segmented simultaneous connection;

2. Configurable integrated quenching liquid circulation cooling system;

3. Adopting a profile structure body, with a high degree of automation;

4. Using CNC system or PLC and variable frequency speed control system to achieve workpiece positioning and scanning, and connecting with power supply through PLC to achieve fully automated production.

Our technology and services

1. We can provide professional solution exploration and design for each user

2. We can provide dedicated matching design for each user’s power supply

3. In many cases, we can meet the production needs of users with more economical and energy-saving equipment

4. We can conduct actual workpiece heating experiments for most users

5. We can provide constructive references and suggestions for improving your production process

6. We guarantee that every rebar heat treatment furnace can operate reliably throughout its lifespan

7. Our rich application experience may also help you solve problems in other aspects

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.