Tube heat treatment furnace

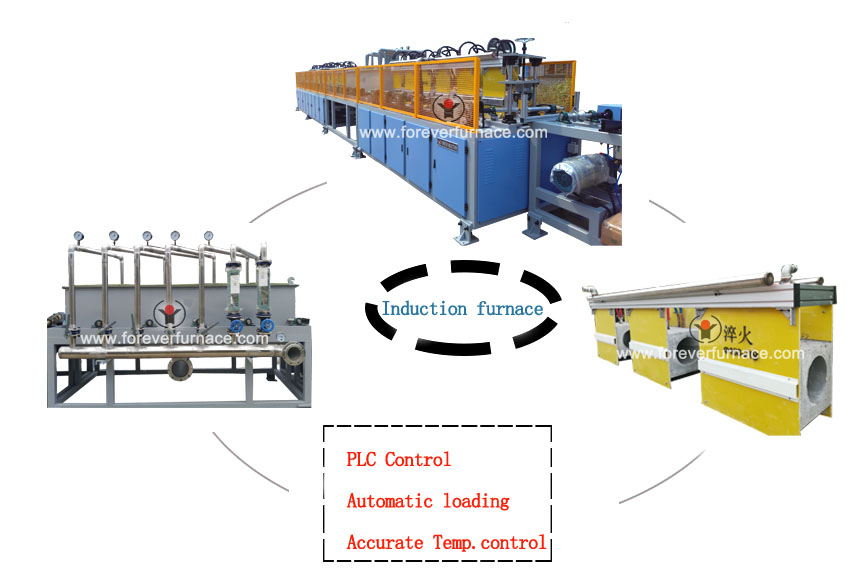

Features:

● Application: Heat treatment line for drill pipes, tubing, casing, OCTG, Erw pipe

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

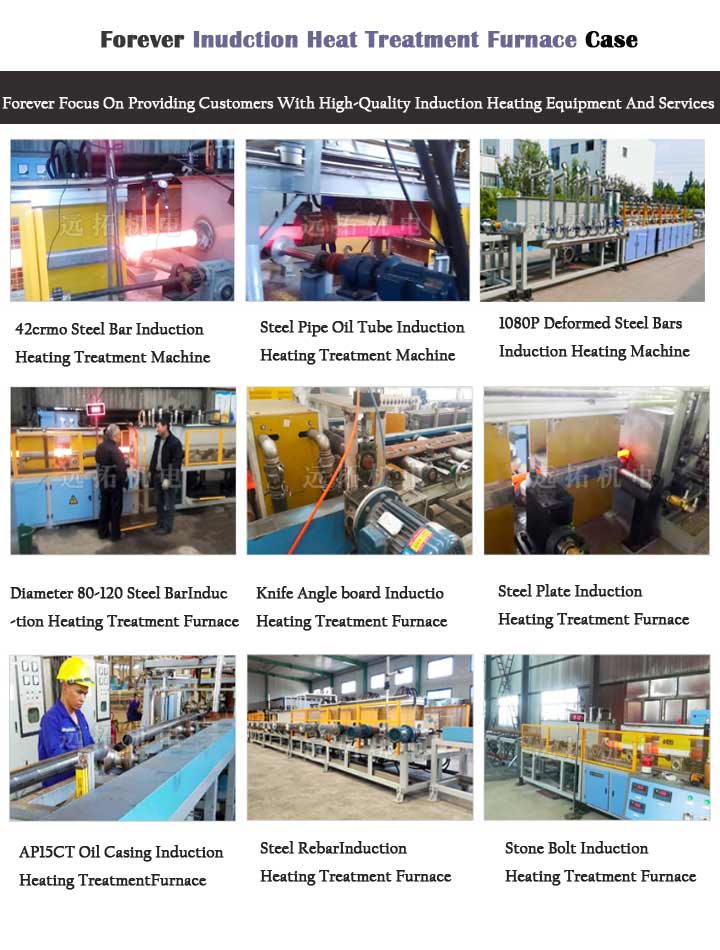

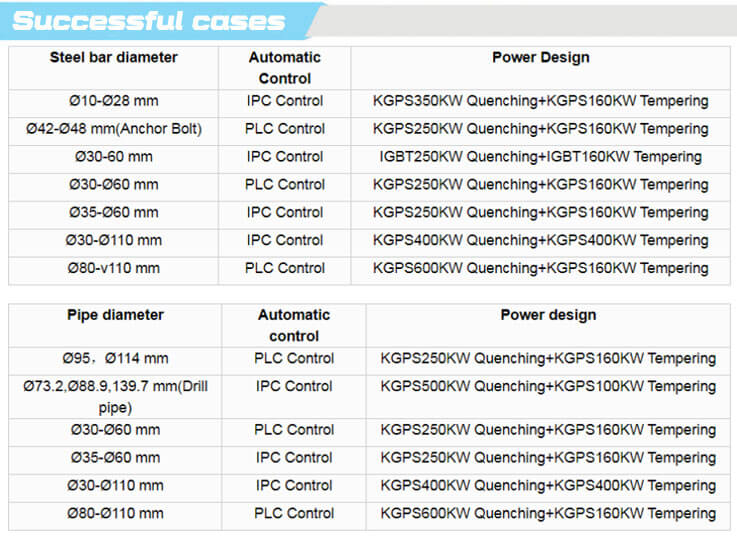

Specialized in customizing tube heat treatment furnace for customers, 14-year induction heat treatment production history has led Forever to the forefront of the field of various kinds of tube heat treatment furnace. Please let us know the tube specification and capacity that you need to do heat treatment, then our engineer will give you suitable proposals.

● Name of equipment: tube heat treatment furnace

● Name of equipment: tube heat treatment furnace

● Equipment brand: Forever

● Material: carbon steel, alloy steel, etc.

● Delivery time: within 20-50 days

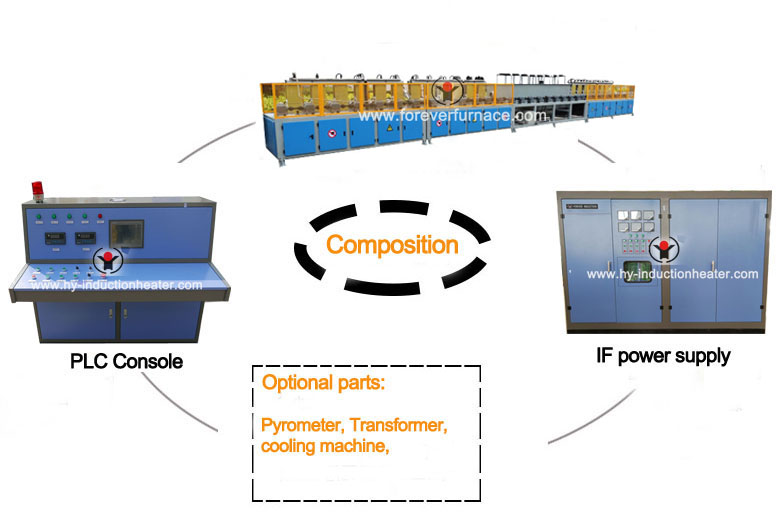

The tube induction heat treatment equipment is controlled by an intermediate frequency power supply.

1.Series resonance design, full open rectifier, high power factor and small resonant component.

2. The cabinet adopts T2 copper bar, which is sandblasted, passivated, low leakage inductance, anti-oxidation and can effectively reduce line loss.

3. Intelligent quality system monitoring system: It can real-time monitor the operation of power supply, powerful database, flexible storage and viewing of process parameters.

4. Parallel resonance design, phase-shifting power regulation, mature and stable equipment; more suitable for larger power.

5. DSP control, speed capture phase locked start, to meet frequent start and stop, the success rate of 100%.

6. Adaptive frequency conversion, frequency range 200-10000Hz, automatic matching induction furnace replacement, without any manual adjustment.

The characteristics of tube heat treatment furnace are:

1. Roller table in front of furnace and between furnace are made of 304 non-magnetic stainless steel. The service life of roller table is greatly prolonged by cooling water.

2.The conveying roller adopts ceramic roller, so that the workpiece can be in operation without wear and anti combustion.

3. The sprinkler system adopts multi-stage stainless steel sprinkler, and the sprinkler pressure and flow are adjusted independently to meet different hardenability requirements.

4. The pipe heat treatment furnace is controlled by Raytek Thermometer of USA. The temperature of the workpiece is displayed in real time and the heating is uniform.

5. After quenching the workpiece does not need straightening, no bending, no deformation, because our quenching and cooling temperature is uniform.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !