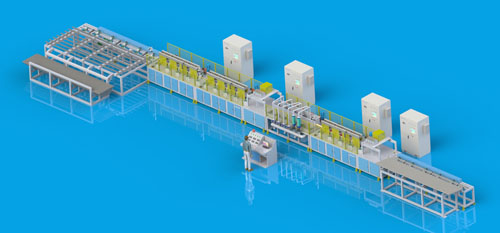

Steel pipe induction quenching and tempering furnace

Features:

[power supply system] quenching power supply: 160kw-1000kw / 0.5-2.5khz; Tempering power supply: 100kw-600kw / 0.5-2.5khz;

[production efficiency] 0.5-3.5 T / h;

Product Detail

Application Video

Product Tags

steel pipe induction quenching and tempering furnace

[power supply system] quenching power supply: 160kw-1000kw / 0.5-2.5khz; Tempering power supply: 100kw-600kw / 0.5-2.5khz;

[production efficiency] 0.5-3.5 T / h;

[conveying roller table] the included angle between the roller table axis and the workpiece axis is 18 ~ 21;, The workpiece rotates and advances at a uniform speed to make the heating more uniform. The roller table between furnace bodies adopts 304 non-magnetic stainless steel and water cooling.

[temperature closed-loop control] both quenching and tempering adopt American Leitai infrared thermometer and form a closed-loop control system with Siemens PLC.

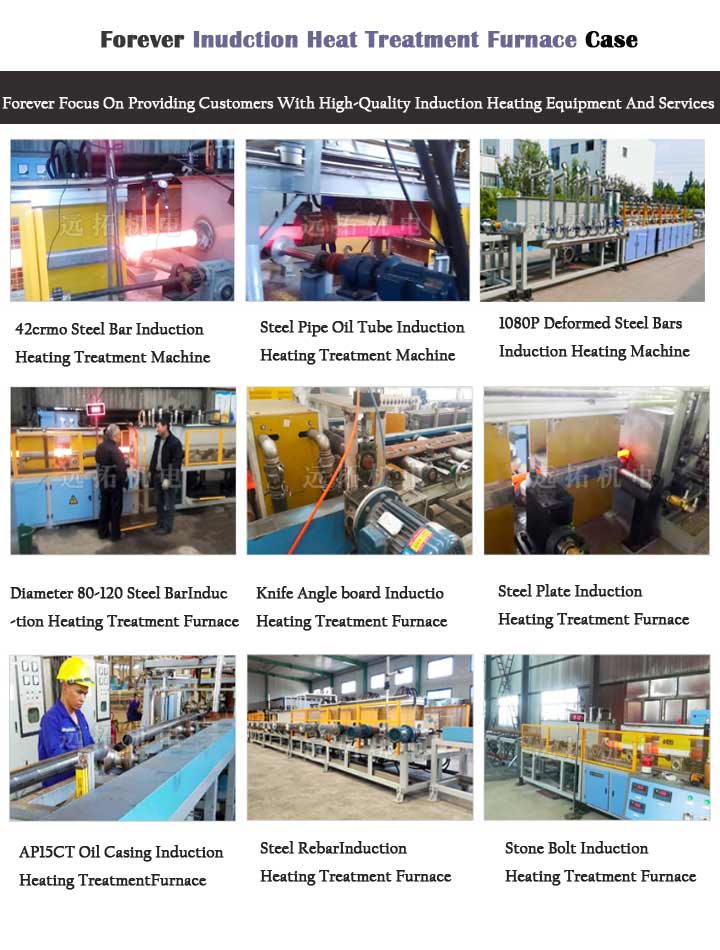

Forever Electromechanical Equipment Manufacturing Co., Ltd. specializes in the production of steel pipe quenching and tempering heat treatment furnace. Its device process is mainly used for the quenching and tempering heat treatment of steel rod, steel pipe, oil drill, metal long beam and other workpieces. The steel pipe quenching and tempering heat treatment furnace adopts PLC man-machine interface full-automatic intelligent control program. You are welcome to inquire about the relevant information of steel pipe hardening and tempering furnace. We will serve you wholeheartedly, Let you buy the ideal induction heating equipment and induction heat treatment equipment!

The steel pipe induction quenching and tempering heat treatment furnace is composed of feeding mechanism, feeding structure, induction heating system, quenching induction heating system, quenching spray system, tempering induction heating system, discharge system, PLC general console and infrared temperature measuring device. The general console of steel pipe heat treatment furnace adopts German Siemens PLC and Taiwan Huayan industrial control system as the core control part to automatically match and adjust the mechanical operation parameters, quenching and tempering parameters and power supply power of the whole induction quenching and tempering system, and display, store and print various parameters.

1. Recipe management function:

The professional formula management system can automatically call relevant parameters after inputting the steel grade, diameter, length and other parameters to be produced, without manually recording, consulting and inputting the parameter values required by various workpieces.

2. Historical curve function:

The traceable process history curve (standard configuration of industrial computer system) can vividly and accurately reproduce the processing temperature trend diagram of a single product. Storage space of up to 1t capacity can permanently store all product process records for decades.

3. History:

The traceable process data table can take out multiple groups of sampling points on each product to accurately reproduce the treatment temperature value of each section of a single product. The touch screen system can store about 30000 process records, which can be backed up by USB flash disk or network; The industrial computer system is completely free from storage space restrictions and permanently keeps all product process records for decades.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)