Classification introduction of steel balls: The steel ball hot rolling equipment can be divided into two categories: casting and forging. The forging production process can be divided into forging and rolling. Forging and rolling are collectively referred to as forging and rolling. Air hammers are usually forged with steel balls.

Steel ball rolling, also known as steel ball skew rolling, is carried out on a skew rolling mill. The oblique rolling forming process has a history of several decades, but in the past decade it has been widely used in the production of steel grinding balls.

Briefly introduced the advantages and disadvantages of the steel ball production process using hot-rolled steel ball equipment:

1. The Rolling steel ball heating equipment has a high output of rolled steel balls, especially in terms of production efficiency, which cannot be compared to cast steel balls. Forging production is twice as much as casting production, and rolling production is dozens of times more than casting production.

2. There are two main reasons for the high quality of rolled steel balls in the hot-rolled steel ball production line: first, the rolled products have streamlined metal fibers; The second is grain refinement after rolling. These two points are also the reasons for the high impact toughness and tensile strength of steel balls during impact.

3. The rolling production of hot-rolled steel balls on the production line is a type of rolling steel balls with good working conditions. If induction heating and automation are adopted, the working conditions of the cutting production line will be greatly improved. Reduce labor intensity and improve working environment.

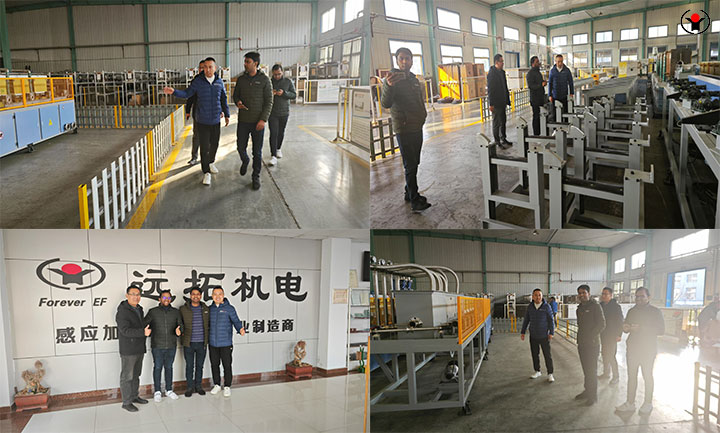

Forever Electromechanical has produced nearly 200 hot rolled steel ball production lines nationwide and around the world. The heating diameter of the steel rod is ∅ 20- ∅ 300, and the length of the steel rod is generally not limited to 6 meters or more. The PLC closed-loop control automatic heating production line can be realized according to customer needs. PLC automatic control can achieve automatic temperature adjustment and automatically track power according to the speed of the hot-rolled steel ball production line. Induction heating equipment adopts network power control, with low power consumption and high production efficiency.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-03-2025