Billet induction reheating furnace for on-line temperature compensation and heating of continuous casting slab for strip rolling is composed of power supply system, induction heating furnace body, slab conveying machinery, control system, infrared temperature measurement feedback, cooling circulation system, etc.

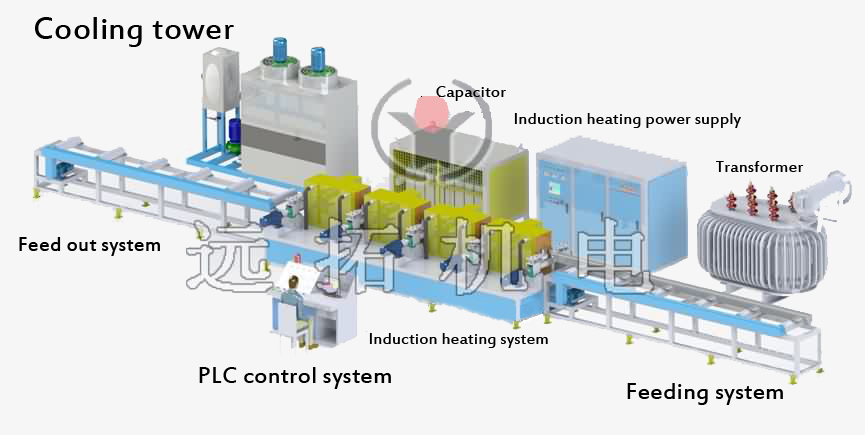

3D diagram of induction heating furnace for continuous casting slab online heating furnace

In the whole production line, the continuous casting billet is heated by the induction heating furnace body; The billet conveying machine is used as the billet conveying device, which is used to precisely transport the continuous casting billet; The infrared temperature measurement is fed back to the temperature monitoring device, so that the temperature difference of each blank is less than 30 degrees; Finally, the PLC remote control system+industrial control computer is used to realize the automatic production of the whole production line, which is applicable to the automatic temperature compensation and heating production of the slab with width of 470mm-610mm, thickness of 80mm-120mm and length of 6000mm-12000mm before rolling strip steel.

Induction heating furnace equipment for continuous casting Billet induction reheating furnace

How much is the price of such a set of induction heating furnace for on-line temperature compensation and temperature rise of strip rolling and continuous casting slab? Due to the size of power supply, the choice of material brand, manufacturing process and details of key parts are different, and the price of equipment is also different.

Post time: 01-23-2023