Continuous production of steel billet online induction heating instead of gas and natural gas heating equipment technical renovation project:

The specialized steel rolling process involves cooling the steel billets produced by steelmaking, transporting them to the rolling mill, and then heating them in a heating furnace before rolling them into steel. induction heating equipment This process has two defects:

After being pulled out of the steelmaking and continuous casting machine, the steel billet has a temperature of 700-900C on the cooling bed, and the latent heat of the steel billet has not been effectively utilized. After the continuous casting billet is heated by a heating furnace, the surface of the billet loses about 1.5% due to oxidation.

Energy efficiency analysis:

The coal consumption of the original heating equipment for heating steel billets is 80 kilograms per ton of steel (with a heating value of 6400 kcal/kg), equivalent to 72 kilograms of standard coal. After the technical transformation, the process energy consumption is 38 kilowatt hours per ton of steel, equivalent to 13.3 kilograms of standard coal;steel billet induction heating equipment

The estimated annual steel production capacity of the steel rolling plant is 600000 tons, so the annual saved standard coal is: (72-13.3) 1000X600000 tons=35220 tons of standard coal

3. Energy saving principle

After the steel billet is pulled out of the continuous casting machine, the surface temperature is 750-850 ° C, and the internal temperature can even reach 950-1000 ° C. One of the basic principles of induction heating is the skin effect, which is the gradual conduction of heat energy from the surface heating to the inside. In fact, one-third of the steel billet does not need to be heated internally. Depending on the cross-sectional size of the steel, different frequencies can be selected to achieve better heating efficiency.Induction heat treatment equipment

4. Energy saving points:

a) The high energy utilization rate of induction heating can reach as high as 65-75%, while the traditional storage heating furnace is only 25-30%.

b) The surface oxidation of induction heating steel billets is only 0.5%, while that of regenerative furnaces can reach 1.5-2%.

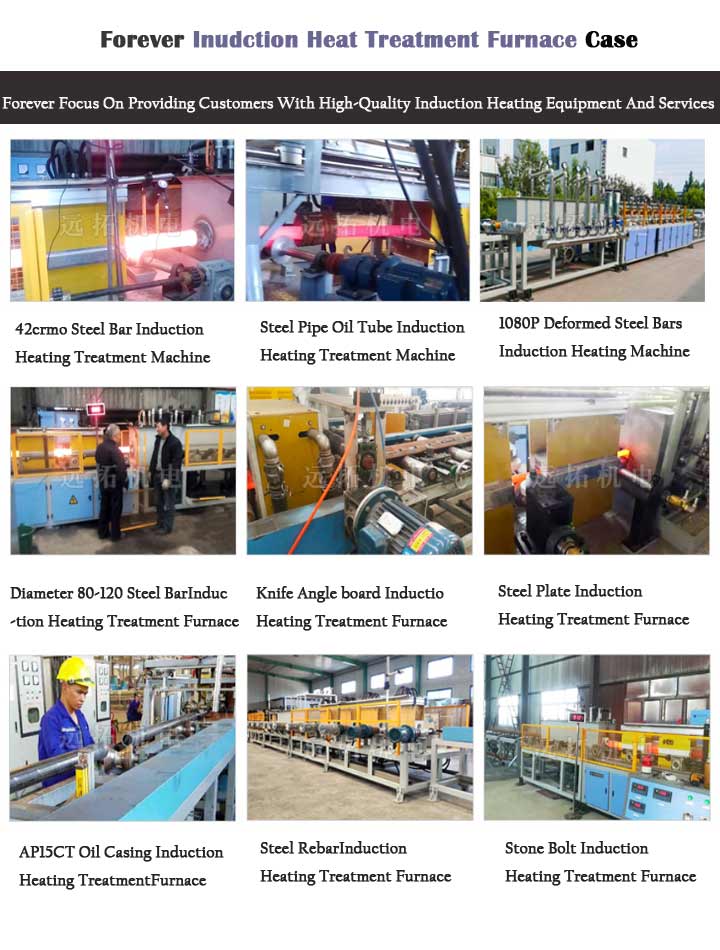

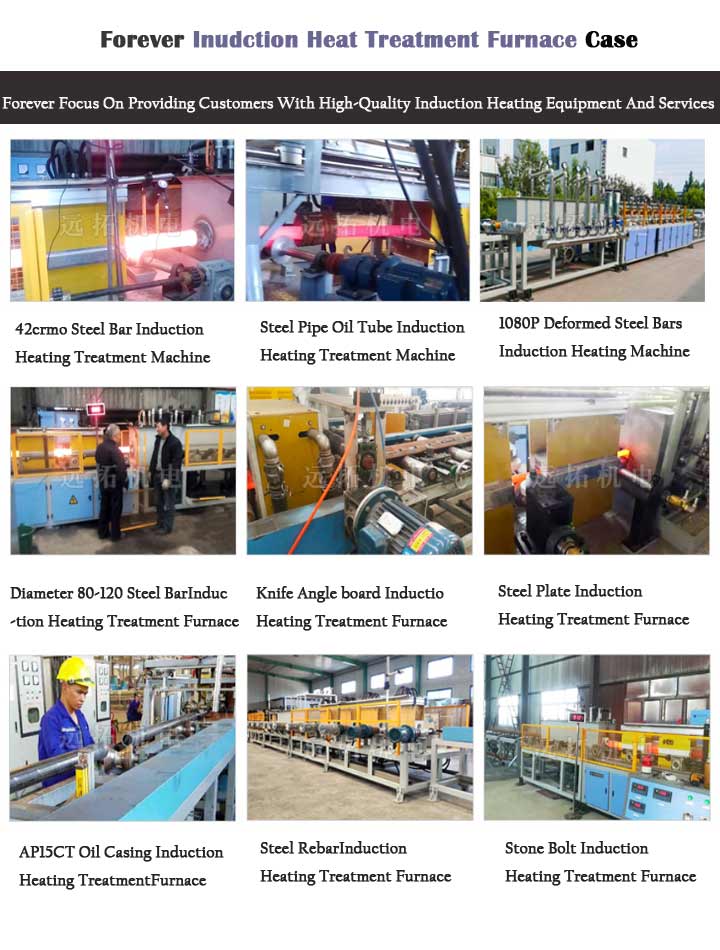

Forever Mechanical and Electrical provides continuous casting billet heating equipment, which adopts PLC intelligent automatic program control throughout the process. The continuous casting billet heating furnace is safe, energy-saving, highly automated, with stable product quality, high production efficiency, and simple operation. By choosing Forever, you can enjoy superior prices because we are a manufacturer produced and directly sold equipment. The device has won a good reputation among new and old users.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 08-22-2023