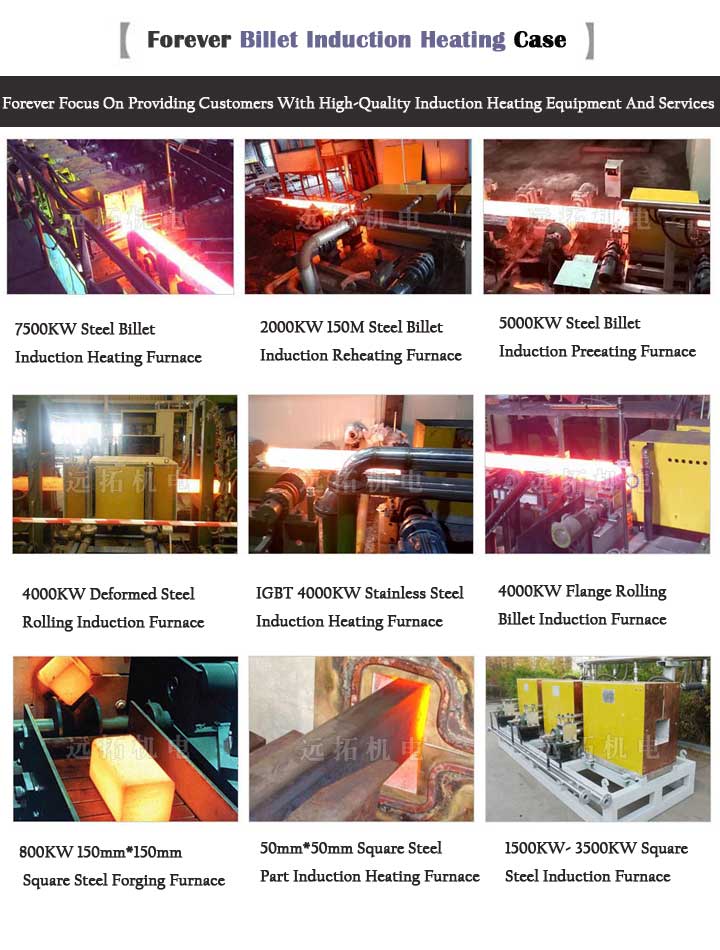

Forever Electromechanical specializes in providing Billet continuous casting production line, PLC fully automatic intelligent control, closed-loop temperature control for continuous casting billet heating furnaces, uniform heating, no overburning, no deformation, no cracks, quality assurance, and free technical solutions and quotations for continuous casting billet heating furnaces for users.

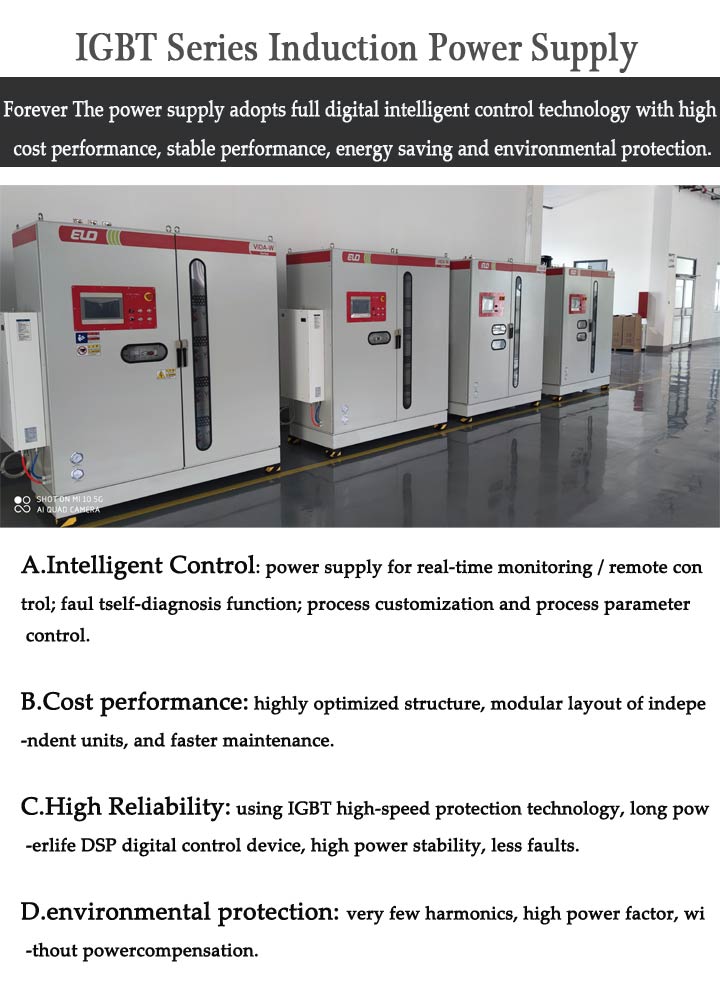

Forever Power adopts fully digital intelligent control technology, which has high cost-effectiveness, stable performance, energy saving and environmental protection.

Intelligent control: The IGBT intelligent induction heating power supply can monitor and remotely control the operating status in real-time; Fault self diagnosis function; Process customization and process parameter control, etc.

High cost-effectiveness: highly optimized structure, modular layout of independent units, faster maintenance, and easy expansion of power supply with development.

High reliability: Adopting IGBT high-speed protection technology, with long power supply life and DSP digital control devices, the power supply has high stability and few faults,

Energy saving and environmental protection: minimal harmonics, high power factor, no need for power compensation.

Billet continuous casting furnace inductor process:

The furnace body of the intermediate frequency induction heating equipment adopts a contour design, and the copper tube is wrapped with T2 oxygen free copper. The wall thickness of the copper tube is greater than or equal to 2.5mm. The insulation material of the furnace body is made of knotted material imported from the United States, which has high strength, high temperature resistance, and longer service life. A water-cooled roller is installed between each section of the furnace body, and each roller is equipped with a variable frequency speed control motor. The two ends of the furnace body are sealed with a whole piece of copper plate,. The furnace chassis frame is made of non-magnetic stainless steel or aluminum alloy to reduce the impact of magnetic leakage and heat generation on other components. Install a water pressure gauge and high water temperature protection for each section of the furnace body.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-23-2025