The surface structure or internal chemical composition of steel bars are changed by heat treatment in order to improve the comprehensive mechanical properties of metal steel bars and make them have higher economic value. Let’s have a deep understanding of the heat treatment process of the steel bar heat treatment system

Heat treatment process generally includes three processes: heating, heat preservation and cooling, sometimes only heating and cooling. These processes connect with each other and are uninterrupted.

Heating is one of the important processes of heat treatment. There are many heating methods of metal heat treatment, first using charcoal and coal as heat source, and then using liquid and gas fuel. The application of electricity makes heating easy to control and no environmental pollution. These heat sources can be used to heat treatment directly or indirectly by molten salt or metal or even floating particles.

Heating temperature is one of the important process parameters of heat treatment process. Selecting and controlling heating temperature is the main problem to ensure the quality of heat treatment. The heating temperature varies with the purpose of the treated metal material and the heat treatment, but it is usually heated above the phase transition temperature to obtain the high temperature microstructure.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

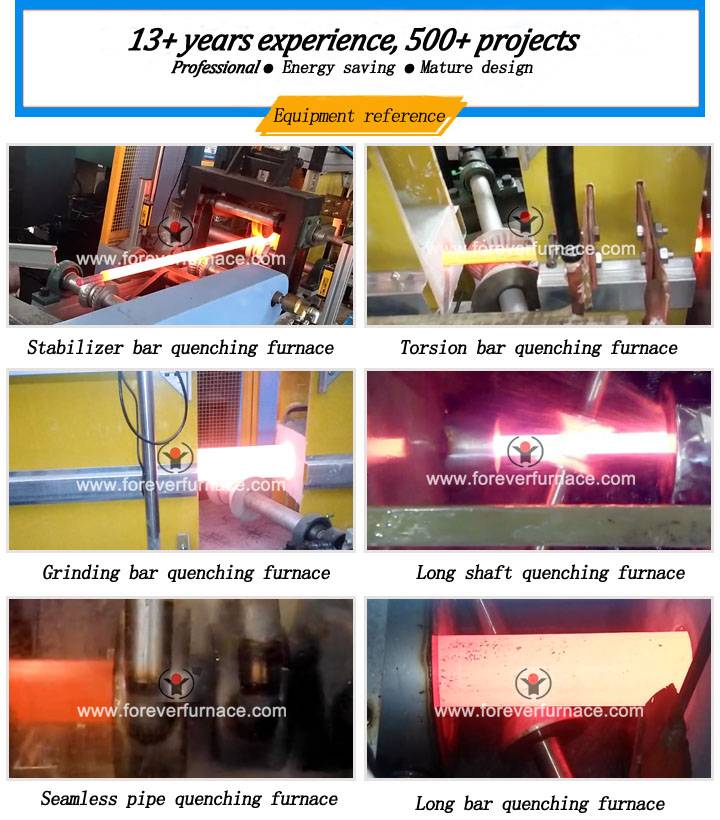

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-24-2019