The surface structure or internal chemical composition of steel rod is changed by heat treatment in order to improve the comprehensive mechanical properties of metal steel rod and make it have higher economic value. Let’s get a deep understanding of the steel bar heat treatment system.

Heat treatment usually consists of three processes: heating, heat preservation and cooling, sometimes only heating and cooling. These processes are intertwined and uninterrupted.

Heating temperature is one of the important technological parameters of heat treatment process. The selection and control of heating temperature is the main problem to ensure the quality of heat treatment. The heating temperature varies with the purpose of the treated metal material and heat treatment, but generally it is heated above the phase transition temperature to obtain the high temperature microstructure.

In addition, it takes a certain time for the transformation, so when the surface of the metal steel bar reaches the required heating temperature, it must be kept at this temperature for a certain time, so that the internal and external temperatures are consistent, and the microstructure is completely transformed. This time is called holding time. When high energy density heating and surface heat treatment are used, the heating speed is very fast, there is no holding time generally, and the holding time of chemical heat treatment is often longer.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

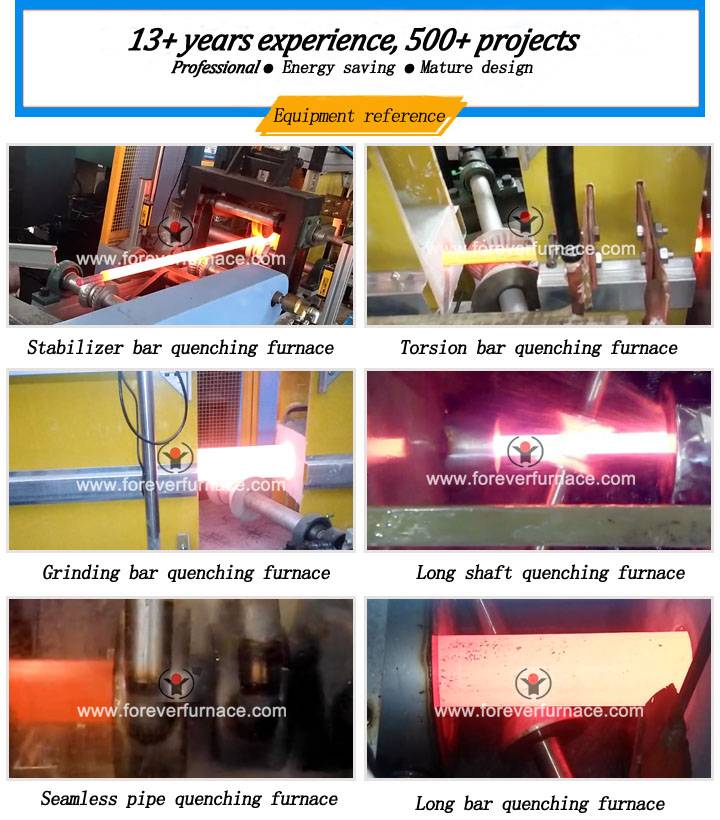

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-27-2019