Enterprises earn 50 million a year just because the rectangle pipe heat treatment furnace, let’s see it !

Induction heating furnace technology principle, first of all, it is combined with electromagnetic induction, which can be instantly heated to the required 1000 degrees high temperature. In addition, it will not be like other heating method that hhe high heat generated first and then heat the other metals. The heat can be generated in the inside of the workpiece. The principle of medium frequency induction heating furnace is the principle of electromagnetic induction, and the changing magnetic field generates electric field. For example, when the electric field changes, the magnetic flux of the rectangular pipe metal will change, and then the current will be generated in the rectangular tube metal. The current will be short-circuited in the rectangular tube metal, so the voltage will be very small. It can generate high current, so that the rectangular tube can be heated rapidly. The principle of electromagnetic induction heating technology is a revolution in heating mode, the same as electric heating, but it can save 40% of electricity than electric furnace, electric oven, etc. This is the strong advantage of induction heating furnace.

Rectangular pipe heat treatment is a clean and rapid quenching process with high power density and fast cooling speed, and only water or cooling water medium is needed. Compared with flame quenching and carburizing quenching, induction hardening layer of rectangular tube is uniform, hardness is high, rectangular tube has no deformation. So better to use steel pipe induction heating equipment for the material austenitizing. The depth of heating layer and heating track are easier to control by PLC intelligent control system. It is easier to realize automation by combining advanced intelligent control science with one-button cold start, according to different tube size. The design of induction heating coil and quenching coil can eliminate the limitation of furnace size in chemical heat treatment such as carburizing and quenching, so it is gradually replacing the traditional process such as flame quenching and chemical heat treatment in many industrial fields.

Especially important is the rectangular tube quenching before and after the deformation of the workpiece can be avoided, so it is particularly suitable for high precision requirements of rectangular tube quenching. The depth of the hardened layer of square tube quenching is generally between 0.3 mm and 2.0 mm, depending on the composition, size and shape of the square tube workpiece and the quenching parameters of the square tube. To quench the surface of large square tube and the Journal of large shaft parts, the requirement of actual working conditions can be met without subsequent processing and straightening. The rectangular tube quenching technology uses heat treatment to heat the substrate to 1100 C~1500 C, and then enters the quenching water tank to complete induction spray quenching. The quenching structure is very dense.

Rectangular tube induction heat treatment equipment has been successfully applied to the integral strengthening of fragile square tubes in metallurgical, mechanical, petrochemical and iron and steel industries, especially in improving their service life, wear resistance and corrosion resistance. Great economic and social benefits have been achieved.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

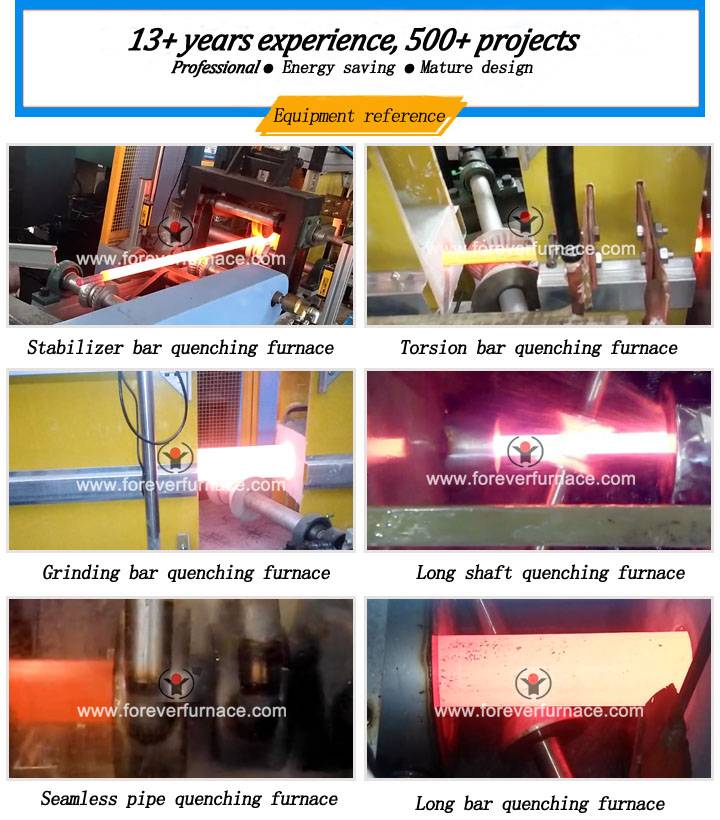

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 09-19-2018