Main technical parameters of sucker rod induction heat treatment system :

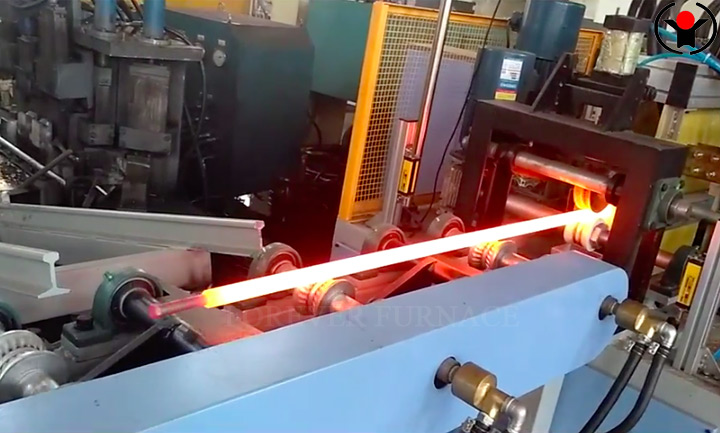

Main application: Suitable for heat treatment of rods such as drill rods, push rods, torsion bars, stabilizer bars, etc.

Power supply system: 160-1000KW/0.5-2.5KHz, hourly output of 0.5-3 tons, applicable range 015-0150

Conveyor roller conveyor: The axis of the roller conveyor forms an angle of 18-21 ° with the axis of the workpiece. The workpiece rotates while moving forward at a constant speed, making heating more uniform. The roller conveyor between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled

Roller grouping: Independent control of the feeding group, sensor group, and discharge group is beneficial for continuous heating without creating gaps between workpieces.

Spray system: It adopts multi-stage spray cooling, and the pressure and flow rate between each level of spray ring can be adjusted to meet the requirements of different hardenability.

Temperature closed-loop control: The quenching adopts a Leitai infrared thermometer and forms a closed-loop control system with Siemens S7, with high temperature control accuracy.

Industrial control computer system: Real time display of the current working parameter status, workpiece parameter memory, storage, printing, fault display, alarm and other functions.

Energy conversion: using quenching method, with a power consumption of 260-280 kWh per ton.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 08-08-2024