Heating is only one of the processes in the process of Metal heat treatment, but if the heating process is not properly heated, there will be a series of defects, even cause the metal material can not be used in normal use. Hebei FOREVER Electrical and Mechanical works share some common problems in heat treatment and heating of metals.

1. During the process of heat treatment, the overheating is most likely to lead to the coarse austenite grain and decrease the mechanical properties of the parts. The theory of heredity of fracture surface is controversial. It is generally believed that the inclusion such as MnS dissolved into austenite and enriched at the crystal interface because of the high heating temperature, and these inclusions precipitated along the grain interface during cooling. It is easy to fracture along the grain boundary of coarse austenite under impact.

2. The overheating temperature is too high, which causes not only the coarse austenite grain size, but also the local oxidation or melting of the grain boundary, which leads to the weakening of the grain boundary, which is called overburning. After overburning, the properties of the steel are seriously deteriorated, and cracks are formed when the steel is quenched. Overburned tissue can not be recovered, can only be scrapped. Therefore, in the work to avoid the occurrence of overburning.

3. When the carbon is heated, the surface carbon reacts with oxygen, hydrogen, carbon dioxide and water vapor in the medium (or atmosphere), reducing the surface carbon concentration called decarbonization, and the surface hardness of the decarburized steel after quenching. The fatigue strength and wear resistance are decreased, and the surface reticulated cracks are easily formed when the residual tensile stress is formed on the surface.

4.The phenomenon of hydrogen embrittlement is called hydrogen embrittlement when high strength steel is heated in hydrogen-rich atmosphere. Hydrogen embrittlement can also be eliminated by hydrogen removal treatment (such as tempering, aging, etc.). Hydrogen embrittlement can be avoided by vacuum, low hydrogen atmosphere or inert atmosphere heating.

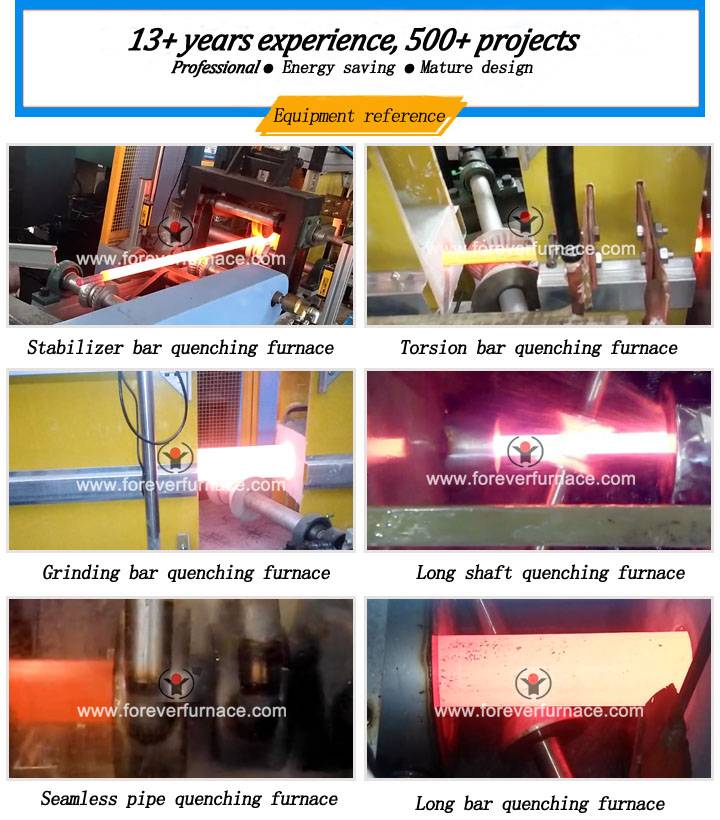

Hebei FOREVER Mechanical and Electrical Plant nearly 20 years experience to build induction heat treatment equipment. qa。 Jiangbei is a large heat treatment quenching equipment manufacturers. The remote induction heat treatment equipment is easy to operate. Production efficiency is high. The equipment is efficient and energy-saving. Durable.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-30-2019