The process should be optimized and the performance of the equipment should be mastered. Priority should be given to high efficiency and reliability in the proper selection of parameters for each segment. Heating insulation and cooling, circulation is not sloppy. The composition of steel has changed, and the effect of phase transformation should be considered. By calculating the modulation parameters, the process is reliable and more suitable.

Iron and steel classification, reasonable choice is more scientific. Heating temperature is very important, insulation time should be sufficient. [-] High alloy steel to be segmented, slow heating is guaranteed. Overheating and overheating are disadvantageous, only more weighing is needed

Insulation time should be taken into account, heating conditions and conditions. The number of parts and wall thickness, select the calculation to grasp the focus. Oxidation decarbonization control, can choose a variety of methods. Creating anaerobic is the key, and the best option is a vacuum.

Part slender vertical, thin-walled more, to prevent deformation. Attention should be paid to the sudden change of cross-section, heating and cooling protection. When cooling is greater than critical value, obtaining martensite is fundamental. Cooling control should be appropriate, appropriate cold and anti-cracking. Ensure the hardness of the foundation and tempering immediately to relieve stress. Temperature adjustment to hardness, different tempering changes of steel.

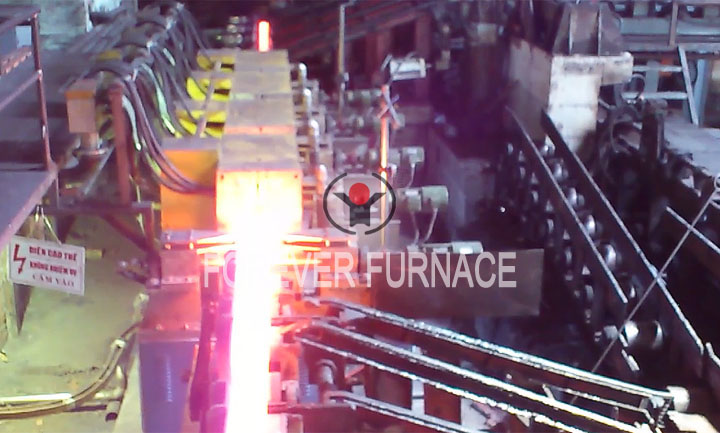

Hardness performance is basic, quantitative relationship can be converted. Master the scientific process, down-to-earth practice. Accumulated experience more summary, practical, fast, reliable. Hebei FOREVER Electrical and Mechanical equipment Manufacturing Co., Ltd. is a professional manufacturer of heat treatment furnaces. By virtue of its rich practical experience in production, Yuantuo has customized Electric induction heating furnace for more than 100 domestic enterprises. Remote induction heating equipment has the advantages of low energy consumption, no pollution, safety and reliability, simple operation, and so on.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-08-2019