N80, P110, Q125, Steel pipe, casing pipe induction heat treatment furnace

With the increasing difficulty of oil exploration, well deepening deepening of the oil well pipe, the strength level requirements are getting higher and higher, J55 steel grade casing has gradually failed to meet the requirements, N80 steel grade has become conventional steel grade, P110, Q125 and other steel grades are more and more widely used, while the pipe market is supplying more J55 steel grade pipe.It’s a difficulty to buy N80, P110, Q125 grade pipe. This poses great difficulties for oil pipe manufacturers to make high-grade oil casings.

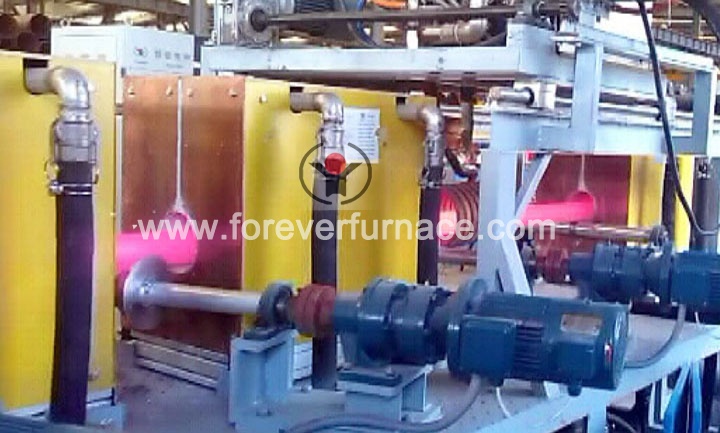

Construction of oil pipe induction heat treatment furnace can improve J55 low-grade pipe to N80, P110, Q125 through heat treatment, which solve the difficulty to purchase high-grade pipe.

Forever induction heat treatment furnace working procedure:

● Lifting the casing pipe on the storage platform;

● Automatic alignment of casing pipe positioning;

● The casing pipe will be transported to roller table;

● Quenching induction heating: Closed-loop temperature control system: continuous online water spraying to active casing pipe completely hardenable: residual water within the pipe will be removed the pipe in the drain platform ;

● Tempering induction heating: Infrared temperature measurement closed-loop control system: to eradicate the oxide scale on the surface of the pipe;

● Cooling bed: Using medium-frequency induction heating as the heat treatment heat source, which has no environment pollution, safety, less scale and low cost.

● The roller table can ensure that the pipe being heated evenly during heating process. After the pipe going through the roller table, you needn’t to use straightening machine to straight the pipes, saving the cost.

● The drain table can make the water and steam remove the pipe and not take into the induction heating coil, so the induction heating coil has longer service life.

Closed-loop temperature control

Set double color infrared thermometer at the outlet of the induction heating coil to monitor the temperature of the workpiece and send the signal to the intermediate frequency power supply, which will automatically adjust the output power of the intermediate frequency power supply to form a closed-loop control system to control the product temperature in the allowable range.

More details about oil casing pipe heating furnace, welcome to contact with us.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating system in China; Glad to be your business partner in induction heating field.

Post time: 12-30-2017