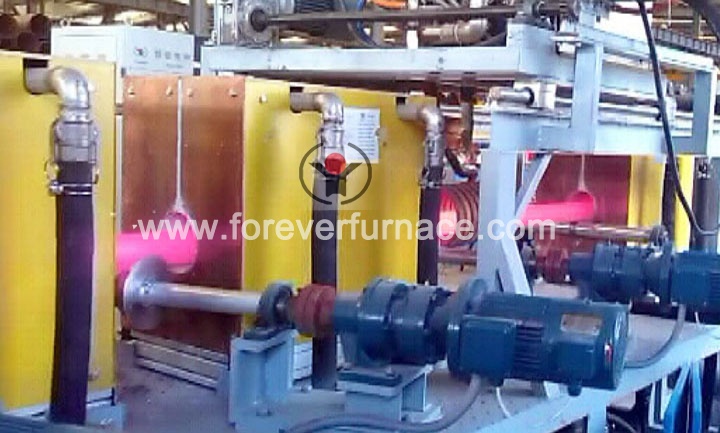

Oil Sucker Rod and Drill Pipe induction hardening and tempering process

Oil sucker rod and drill pipe induction hardening and tempering equipment produced by Forever has made full use of induction heating advantages and we can provide perfect heat treatment process for oils sucker rod and drill pipe.

Sucker rod and drill pipe are all used for oil industry, so it has high requirement for the hardness, toughness, tensile strength and yield strength. Only after hardening and tempering processing, sucker rod and drill pipe internal structure performance can meet the above requirements.

What’s more, sucker rod and drill pipe has different shape from the round rod or pipes. The ends of sucker rod and drill pipe have more thickness. That brought difficulty for the induction hardening and tempering equipment. As the ends wall thickness is more than pipe body, it need special design during induction hardening and tempering processing.

Forever induction hardening and tempering equipment includes storage platform, workpiece alignment system, conveying roller table, induction heating system for austenitizing, quenching cooling tank, induction tempering system, closed loop temperature control system and so on. What’s more, Forever can equip closed cooling tower and transformer for the line.

The working process:

Lift the sucker rods on the storage platform →Transmission roller table→Induction heating→-Cooling in water spray tank→Transmission roller table→Induction heating for tempering→Air cooling device to cooled to 200℃→Secondary tempering for heating the ends→Discharging device—Receiving sucker rods.

For some smaller diameter sucker rod and drill pipes, it will easily bend during heat treatment. According to this, we take some measures to solve this problem: 1.The roller will have 18-20°angle with the roller table, so the sucker rod will rotate by itself while going forward. 2.There is meters for water flow, pressure and temperature on the cooling tank to ensure the workpiece can be sprayed with uniform water pressure and flow. 3.For the induction heater, we design heater for preheating and heater for warm-up. The temperature will be increased continuously.

If you are looking for induction heat treatment furnace for sucker rod or drill pipe. Welcome to contact with us.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating system in China; Glad to be your business partner in induction heating field.

Post time: 03-15-2018