Prevention methods and remedial measures for deformation in heat treatment process

The steel will appear deformation and quenching defects due to various reasons during heat treatment. In the production and processing, the defects that the steel will easily appear after quenching frequently: deformation, cracking, oxidation, decarburization, lesshardness or nonuniform heating. This article will come to the specific details of steel heat treatment quenching deformation, cracking prevention methods and remedial measures.

About the prevention of deformation, cracking, we should do prevention and remediation based on the causes.

1.Unifrom heating as much as possible and heating the workpiece correctly.

If the workship has complex shape or interface size has difference, it often result in uneven heating caused by deformation. Therefore, for the parts which doesn’t need quenching holes and interface mutations, you should use asbestos rope clogging or banding and other ways to improve its heating conditions. For some thin-walled rings and other easily deformable parts, you can design specific quenching fixture. These measures are not only conducive to heating evenly, but also conducive to cooling evenly.

2. Correctly select the cooling method and cooling medium

Using pre-cooling: Before the workpiece went into the cooling medium, try the best to make the workpiece temperature slowly to reduce the workpiece temperature difference.Under the condition that ensuring meeting the quenching layer depth and hardness, try to use the slow cooling quenching medium. Reasonable selection and useing graded or isothermal quenching process.

3. Correctly choose the ways and operation direction that the workpiece immerse the quenching medium.

Quenching should try to ensure that the most uniform cooling with the direction for quenching with the smallest resistance. For the mass production of thin ring parts, thin plate-shaped parts, complex shape of the wheel and bevel gear, it is difficult to ensure the accuracy of dimensional requirements in the free cooling. So you can take the bed quenching.

4 .Timely and correct tempering

In production, there is a considerable part of the workpiece which will not crack in the quenching cracking. It’s because the parts didn’t tempering in time after quenching. During the quenching process, the microfractures present in the workpiece are fused and expanded under a large amount of quenching stress so that their dimensions reach the critical fracture size, resulting in delayed fracture. Practice has proved that timely tempering after quenching is the effective measure to prevent cracking. For the complex shape of high-carbon steel and high-carbon alloy steel, quenching and timely tempering is particularly important.

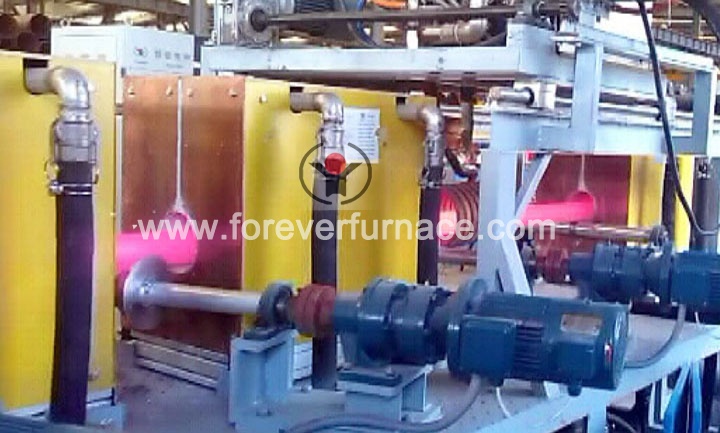

Forever has more than 13 years of experience of steel heat treatment in China. With advanced induction heat treatment technology, and rich steel heat treatment experience, we have helped many users to achieve heat treatment with good effect. With our induction heat treatment furnace, the parts can get good yield strength, tensile strength and straightness.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating system in China; Glad to be your business partner in induction heating field.

Post time: 10-30-2017