The production line can quench and temper (quench and temper) steel bars with a diameter of 120-140mm. The heating mode is online continuous heating. The complete set of round steel quench and temper heat treatment furnace production line only needs a crane to lift the steel bars onto the storage rack, and other actions are automatically completed by the system under PLC control. The complete set of production line adopts computer automatic control to store the mechanical operation parameters, quenching and tempering parameters, temperature and other parameters of the whole system Display, record and print automatically, and the system operates automatically according to the set process parameters.

The complete set of Induction hardening and tempering equipment is composed of medium frequency quenching system, medium frequency tempering system, closed water cooling system, storage rack, quenching mechanical feeding device, infrared temperature measurement, spray cooling system, tempering mechanical feeding device, blanking rack and central control system.

The equipment has the characteristics of rapid heating, uniform quenching, small deformation, low carbon and environmental protection, high efficiency and energy saving, controllable temperature, repeatable operation, high automation, simple and convenient operation, etc.

The power supply system of the equipment adopts full digital intermediate frequency power supply, and its core components adopt high-performance, high-density, large-scale special DSP + FPGA composite integrated circuit, so that all circuits can be digitized, with high reliability, strong anti-interference ability and fast response speed.

Round steel quenching and tempering furnace supporting power supply + PLC

According to different parameters of workpieces, different inductor groups are optimized and designed by computer to meet the high heating efficiency of workpieces in a wide range of sizes. The number of tempering inductors in each group is increased and thermal insulation barrels are added to obtain good tempering structure and ensure that the performance of workpieces meets the requirements.

The spray system adopts a ring-shaped spray device made of stainless steel. It is installed at the discharge end of the inductor. The steel pipe passes through the sprinkler. The high-pressure cooling water is sprayed from the spray hole on the inner wall of the sprinkler to quench the workpiece. There is a water collecting tank under the sprinkler. The cooling water flows into the quenching circulating water tank through the water collecting tank, which saves water consumption to a certain extent.

The control system of the equipment adopts PLC and 10 inch color touch screen, which can monitor the production situation in real time and facilitate digital automatic operation.

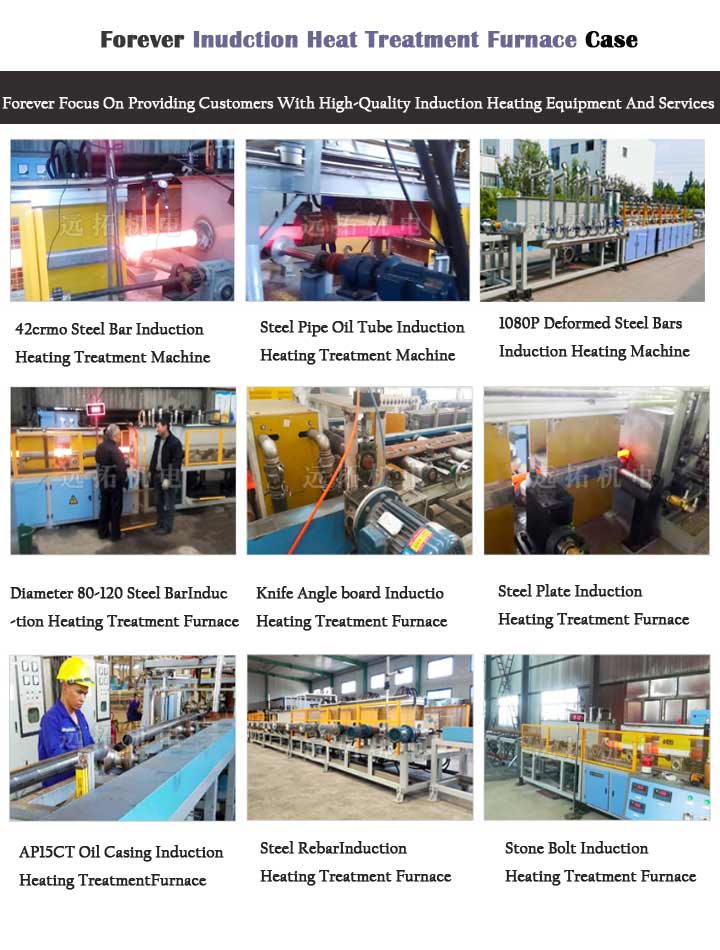

As an old brand manufacturer in the heat treatment industry, FOREVER electromechanical Co., Ltd. will carefully create an bar induction hardening and tempering machine solution suitable for you. We will match and customize it for you according to your actual production needs to ensure that you have no worries in the future production process. If you have problems with the equipment related to the round steel quenching and tempering heat treatment furnace, it is recommended that you find a professional engineer to solve them!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 08-26-2022