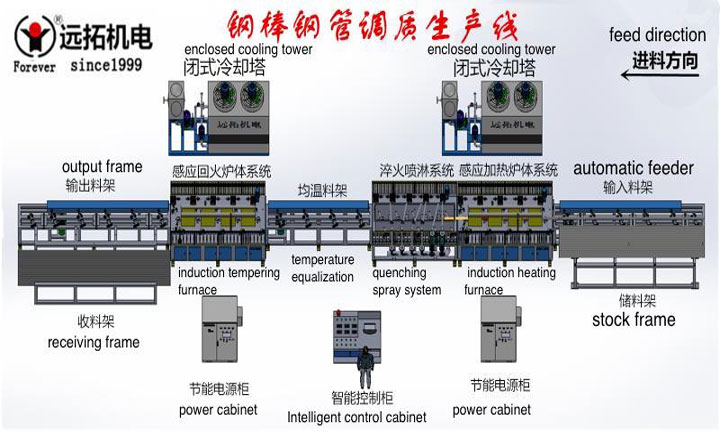

Recommended by the manufacturer of round steel bar tempering production line – Hebei FOREVER mechanical and Electrical Co., Ltd., FOREVER products steel bar heating furnace, steel heating equipment, steel bar heat treatment furnace, steel pipe heat treatment furnace, etc. have the characteristics of high quality, stable performance, high output, etc., and customized round steel bar tempering production line according to the nature of workpiece and the needs of customers.

Main technical parameters of round steel bar quenching and tempering heat treatment equipment:

1. Power supply system: quenching power supply + tempering power supply

2. The output per hour is 0.5-3.5 tons, applicable range: more than 20-120mm.

3. Conveying roller table: the axis of the roller table and the axis of the workpiece form an included angle of 18-21-deg.; the workpiece rotates while moving forward at a constant speed to make the heating more uniform. The roller table between furnace bodies adopts 304 non-magnetic stainless steel and water-cooled.

4. Roller table grouping: the feed group, inductor group and discharge group are controlled independently, which is conducive to continuous heating without gaps between workpieces.

5. Temperature closed-loop control: both quenching and tempering are controlled by American raytime infrared thermometer closed-loop control system, with precise temperature control.

6. Industrial computer system: real-time display of the working parameter status, workpiece parameter memory, storage, printing, fault display, alarm and other functions.

7. Energy conversion: adopt quenching + tempering mode, power consumption per ton is 280-320 degrees.

8. Human machine interface PLC automatic intelligent control system, one key start, production worry free.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-15-2020