Screw bolt induction hardening and tempering equipment

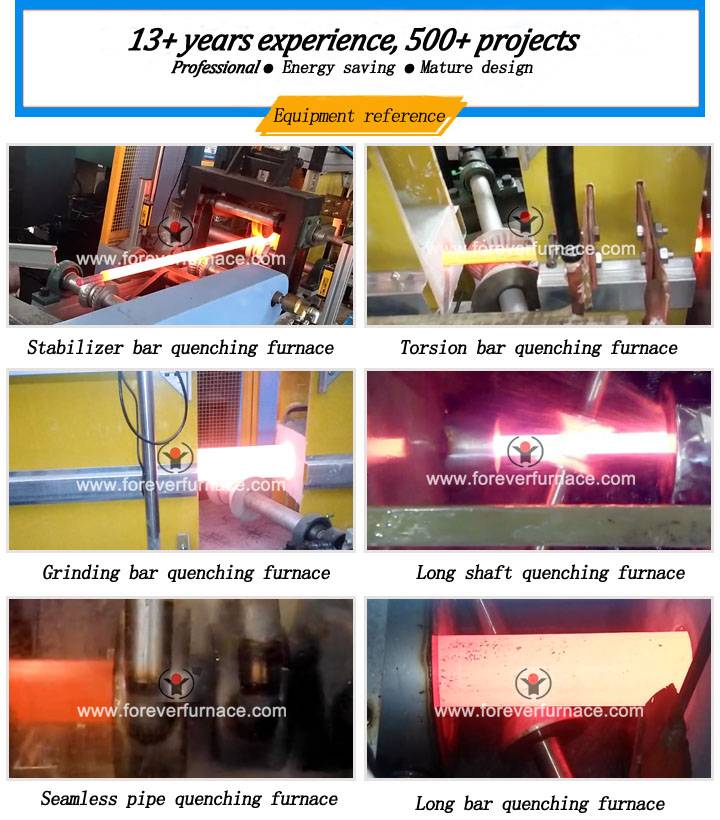

Yuantuo is committed to the production and design of screw bolt induction hardening and tempering equipment with more than 13 years of rich experience. The technology is mature and stable, and the operation is reliable. The screw bolt hardening and tempering equipment has one-button operation, and one person can control the entire set of screw bolt induction hardening and tempering equipment The production line has complete data monitoring, process records, and strong traceability in the production and operation of the line. The customized man-machine interface of the screw bolt induction hardening and tempering equipment always displays production data. The professional technical team provides you with high-quality induction heating equipment and satisfactory service.

Equipment name: screw bolt induction heat treatment equipment

Equipment brand: Yuantuo Electromechanical

Non-standard customization: yes

Workpiece material: carbon steel, alloy steel, etc.

Delivery period: 30 days

Payment method: 40% down payment, acceptance, pay the balance

Screw bolt induction hardening and tempering equipment implementation standards:

1.JB/T4086-85 “Technical Conditions for Electronic Control Equipment for Medium Frequency Induction Heating”

2. GB/T10067.3-2005 “Electric heating equipment basic technical conditions-induction heating equipment”

3.GB/T10063.3-88 “Test Methods for Electric Heating Equipment”

4. GB/T5959.3-88 “Electrical Equipment Safety”

Screw bolt induction hardening and tempering equipment configuration:

● Hardening power range: KGPS160-1300KW

● Tempering power supply range: KGPS160-750KW

Hardening and tempering inductors (including capacitors, water lines, gas lines, etc.)

● Closed cooling system for medium frequency power supply and induction heater.

● Copper row connection wire (connection line between power cabinet and induction furnace)

●Input and output system (The roller is 304 non-magnetic stainless steel. The workpiece rotates at one side and feeds at a constant speed. The operation is stable, the speed is adjustable, the heating is more uniform, corrosion resistance, and long service life)

● Hardening and tempering sprinkler system

● The central console (including frequency conversion speed control and temperature control, Huauan IPC, remote start, etc.) is used to operate the entire set of hardening and tempering equipment directly on the center console, requiring only one person to operate the entire equipment, saving labor,save costs.

●Hardening and tempering infrared temperature measuring device (with Raytek infrared thermometer real-time display the temperature of the workpiece, so that the workpiece heating temperature can be seen at any time in the quenching and tempering process)

●PLC control system (can control the operation of the entire set of mechanical part, human-machine interface, all-digital, highly humane operation)

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating system in China; Glad to be your business partner in induction heating field.

Post time: 03-26-2018