This set of Steel bar hardening and tempering equipment mainly treats steel bars with a diameter of 36-105mm and a length of 3000-12000mm. The heat treatment process includes quenching temperature of around 950 ℃ and tempering temperature of around 750 ℃, meeting the mechanical performance requirements of L7 grade for B7 material. The monthly production capacity is designed to be 2000 tons, with 26 days per month and 20 hours of work per day to ensure efficient production.

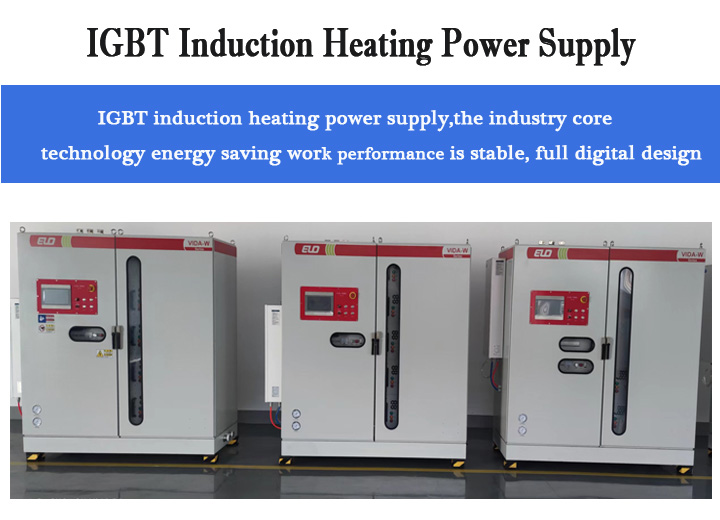

In response to these specific requirements, the steel bar heat treatment equipment designed by Forever is equipped with IGBT power supply and intelligent control system to ensure efficient and stable hardening and tempering heat treatment process. It adopts modular design and utilizes intelligent series IGBT power supply combination to achieve precise hardening and tempering control.

The power supply of the long bar induction heat treatment machine uses IGBT power supply with very few harmonics and a power factor of 0.92 or above, ensuring the efficient operation of the hardening and tempering furnace, reducing user investment. The steel bar heat treatment equipment is equipped with independent, variable frequency speed regulating motors and induction heating furnace bodies. The modular design is easy to maintain and replace, and the real-time monitoring system records workpiece temperature and production data, facilitating quality control and process optimization.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-11-2024