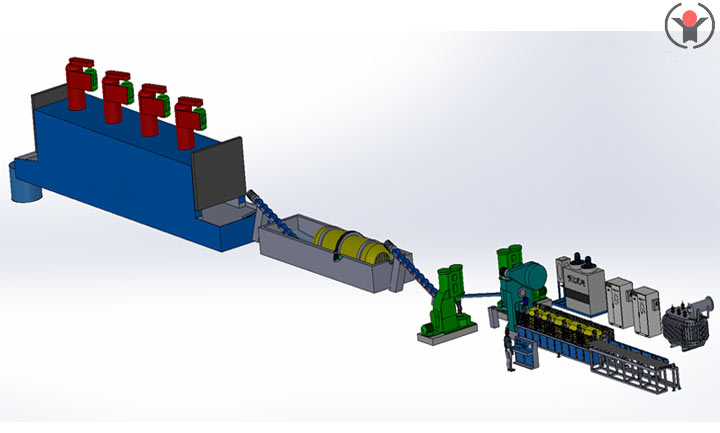

Forever designed this 200 kW round steel ball hot rolling production line , it mainly consists of a storage rack and flipping mechanism, a bar material conveying device, an induction heating system, a PLC control panel, an IGBT induction heating power supply , and a rolling mill.

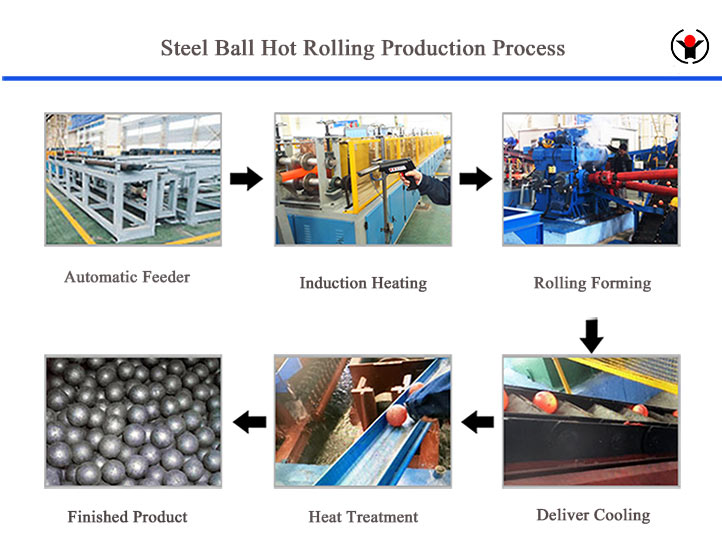

This Induction Heating furnace for hot rolling steel ball is designed specifically for rolling and heating round bars with a diameter of 25mm and a length of 6000mm. It can heat steel bars to 1000C and produce 100 steel balls with a diameter of 25mm per minute. In the steel bar heating and rolling steel ball production line, the steel bar enters the bar material conveying device through the storage rack and flipping mechanism, and then enters the induction heating system for heating. The infrared temperature measuring device monitors the temperature of the steel bar in real time to ensure uniform heating. The heated steel bar enters the rolling area and is rolled into steel balls with a diameter of 25mm using spiral hole oblique rolling technology through two cross rotating rollers. The entire process is automatically controlled by the PLC control panel.

The steel balls produced by the Forever round steel steel ball hot rolling equipment have precise dimensions, smooth surfaces, high internal density, good mechanical properties, and high hardness.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

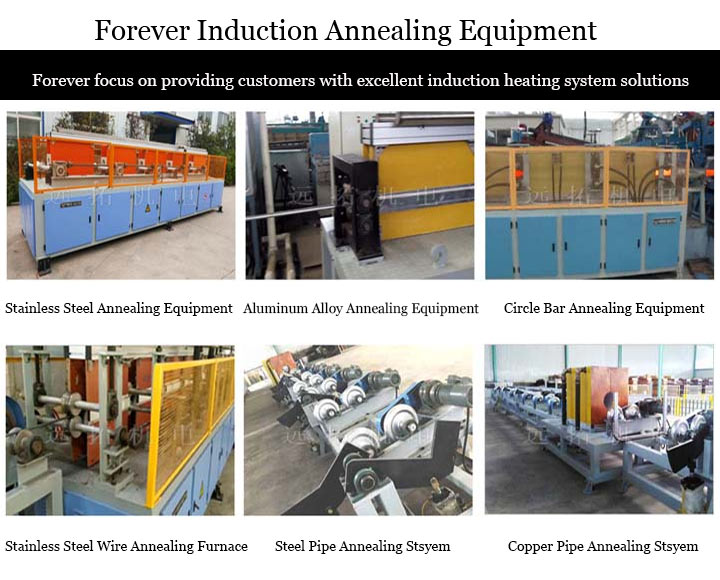

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 09-09-2024