The continuous billet hot rolling machine has high heating efficiency. It uses a solid-state power supply to efficiently provide a magnetic field to the coil. Before entering the rolling mill from the continuous casting machine, the billet and square billet are generally heated to the rolling temperature. Choosing induction heating will evenly heat the billet, with fast speed, high efficiency, and uniform temperature control.

Characteristics of Continuous casting billet reheating furnace

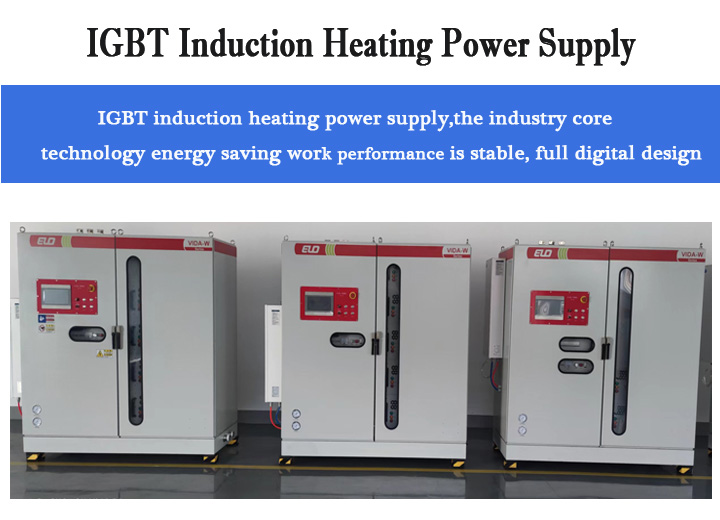

1. IGBT energy-saving power technology, high conversion efficiency: more energy-efficient and environmentally friendly compared to gas and coal-fired furnaces

2. High startup success rate; Power factor>95%: No special foundation required, low operating cost, simple operation

3. Modular design, easy maintenance and repair: using our independently developed new power supply, it saves 10% to 15% electricity, has no harmonics, high load output voltage, low load coil current, and low power consumption.

4. We can provide customers with a dedicated transformer for electric furnaces: this continuous casting billet induction heating furnace adopts DSP control technology, with a reasonable structure, easy debugging, and good performance. It has automatic protection functions for water temperature, water pressure, phase loss, overcurrent, undervoltage, etc.

5. Using branded components to reduce failure rates, ensure reliable equipment operation, and reduce the probability of downtime caused by failures.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-03-2024