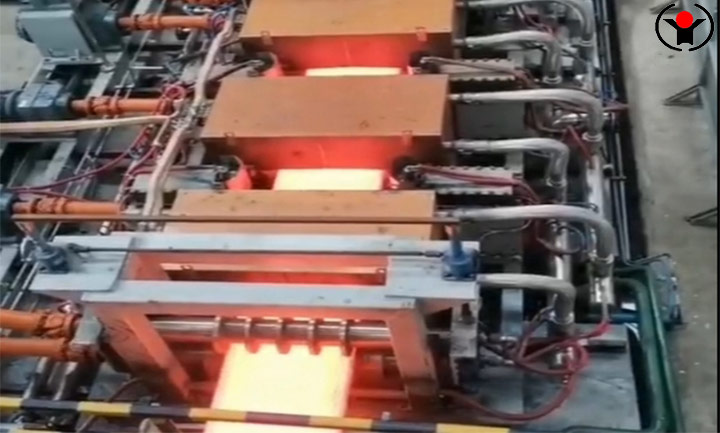

Working principle of Steel plate heat treat furnace:

The working principle of steel plate induction heating equipment is based on the principle of electromagnetic induction. The magnetic field generated by the current in the induction heating coil causes eddy currents inside the metal steel plate. These eddy currents, under the heat generated by the resistance, heat the steel plate to the desired temperature.

Application of Plate induction heat treatment furnace :

1. Steel heat treatment: The steel plate is subjected to heat treatment processes such as quenching and tempering.

2. Metal forming: used to heat steel plates for forging, mold heat treatment, etc.

3. Welding: Used to preheat welds and improve welding quality.

4. Electronic component manufacturing: used for heating and forming metal sheets.

Operation of steel plate induction heating equipment:

1. Set parameters: including operating frequency, power, heating time, etc.

2. Place the workpiece: Place the steel plate that needs to be heated in the induction heating equipment.

3. Start the device: Start the device to perform the heating process.

4. Temperature monitoring: Monitor the temperature of the steel plate during the heating process through a temperature control system.

5. Stop the device: Stop the device after reaching the set temperature or heating time.

Selection of Steel Plate Induction Heating Equipment:

1. Power requirement: Select the appropriate power according to the size and requirements of the heated workpiece.

2. Frequency selection: Different frequencies are suitable for different types of materials and heating depths.

3. Control system: Consider the accuracy and stability of the temperature control system.

4. Safety: The equipment should comply with safety standards and have functions such as overheating protection.

Maintenance of steel plate induction heating equipment:

1. Cleaning and maintenance: Regularly clean the inside and outside of the equipment to prevent dust and debris from affecting heat dissipation and work efficiency.

2. Check the circuit: Regularly check the electrical circuit to ensure that the electrical system is functioning properly.

3. Lubrication: Lubricate the moving parts of the equipment to ensure smooth operation.

4. Regular calibration: Regularly calibrate the temperature control system to ensure the accuracy of temperature control.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-09-2024