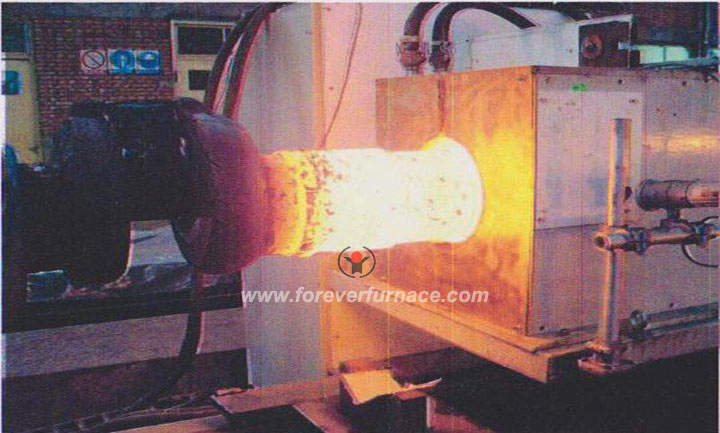

Steel tube induction heating machine is widely used in heat treatment. With the rapid development of metal workpiece thermal processing industry, the production and processing quality is getting higher and higher, the traditional Metal heat treatment equipment has been unable to meet the requirements of users, induction heating equipment.

Where exactly is the steel pipe electrothermal treatment equipment good?

1. Structural design for mechatronics. Able to work directly, installation and debugging simple and fast, eliminate the cumbersome infrastructure installation and man-hour consumption;

2. Heating without open fire: steel pipe electrothermal treatment equipment using a new medium frequency electromagnetic induction principle heating, greatly improve the safety of equipment use, greatly reduce the casualties caused by careless operation and enterprise accident rate;

3. The whole set of steel tube electrothermal treatment equipment has compact structure and less than the traditional flame furnace 2/1, which saves space for users, and the full load of the equipment is over 99%, which can be produced continuously for 24 hours;

4.High degree of automation, steel tube electrothermal treatment equipment can be fully automatic unmanned selection of automatic feeding and automatic discharge sub-inspection device, coupled with our company’s special control software, can achieve fully automatic unmanned operation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 01-14-2020