The use of medium frequency steel pipe induction heating furnce can achieve efficient and uniform stress relief treatment, greatly improving the mechanical properties and service life of steel pipes.

This device generates high-frequency eddy currents through electromagnetic induction to synchronously heat the inner and outer layers of the steel pipe, quickly reaching the preset temperature, eliminating internal stress, and thereby improving the strength and toughness of the steel pipe.

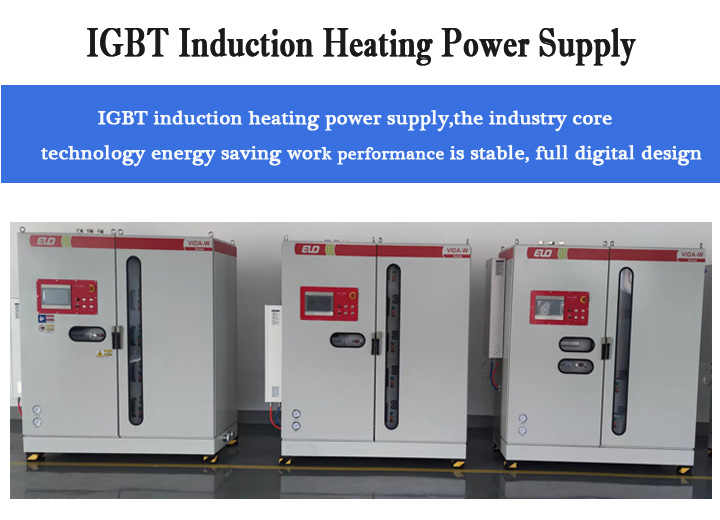

The steel pipe heating equipment mainly consists of induction heaters, cooling devices, control systems, and power supply systems.

Induction heaters are composed of copper coils that generate electromagnetic fields through high-frequency currents.

The cooling device adopts water cooling method to maintain stable equipment temperature.

The control system accurately monitors and adjusts the power and temperature during the heating process to ensure uniform heating of the steel pipe.

The power system provides the required electrical energy, mechanical structure, and conveying system to ensure the stable and continuous movement of the steel pipe during the heating process.

The stress relief heating process of the steel pipe heating furnace is simple and efficient. The steel pipe enters the induction heating through the conveying system, and the high-frequency electromagnetic field of the device quickly heats it to the set temperature. The real-time monitoring and automatic adjustment functions ensure that the steel pipe is evenly heated and eliminate internal stress.

Hebei Forever Electromechanical designs induction heating systems based on customer processing requirements and production processes. Welcome to inquire!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-15-2024