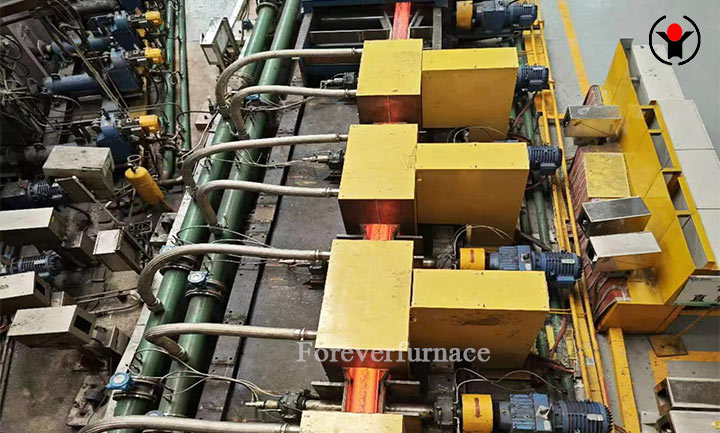

The steel billet induction heating equipment in Forever continuous casting and rolling is designed specifically for 100mm to 200mm square billets, with a suitable length range of 3000mm to 12000mm. The hourly output can reach 40 tons to 300 tons, and the power supply system provides a power of 1000 kW to 12000 kW, with a frequency of 500-1200HZ. It supports independent use of a single power supply or parallel use of multiple power supplies.

The feeding system of the billet induction reheating machine adopts independent motor reducers for each axis, and is equipped with multi axis drives controlled by a single frequency converter to achieve multi axis synchronous operation and ensure the smoothness of steel billet transmission. The guidance system uses 304 non-magnetic stainless steel guide wheels, which have moderate elasticity in the axial direction and are suitable for small bending of steel billets.

The temperature control of the Induction billet reheating furnace consists of a closed-loop system consisting of an infrared thermometer and a PLC. The power supply is automatically adjusted based on the initial temperature and feed rate of the steel billet to ensure a constant heating temperature before being discharged. The industrial computer system supports real-time display of current working parameters, workpiece parameter memory, storage, printing, fault alarm and other functions, and automatically adjusts the power supply to maintain a constant temperature.

Forever Electromechanical provides professional induction heating system solutions according to customer needs.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 02-21-2025