steel pipe induction annealing furnace is a specialized equipment for steel pipe heat treatment, whose main function is to improve the microstructure and mechanical properties of steel pipes through heating, insulation, and slow cooling processes. The annealing process can eliminate structural defects in steel, homogenize chemical composition, refine grains, improve toughness and plasticity, while reducing hardness, making the material easier for subsequent processing.

The working principle of a Steel pipe annealing equipment usually includes the following steps:

1. Heating stage: The steel pipe is sent into an annealing furnace, where it is heated by high-temperature combustion gas or electric heating elements generated by a burner. The heating temperature is usually set according to the material of the steel pipe and the required annealing effect.

2. Insulation stage: After heating the steel pipe to an appropriate temperature, it will be kept in the furnace for a certain period of time to ensure that the steel undergoes sufficient or partial phase transformation inside.

3. Cooling stage: After insulation, the steel pipe will be slowly cooled inside the furnace or through a specific cooling device. The control of cooling rate is crucial for the final material properties.

The design of a Steel pipe induction annealing furnace may include a continuous operation furnace type, which can continuously process steel pipes and improve production efficiency. The furnace is usually equipped with stirring fans and properly arranged electric heating elements to ensure uniform temperature and atmosphere distribution, thereby achieving high-quality annealing results. In addition, modern annealing furnaces may also include automated control systems, such as programmable logic controllers (PLCs), for precise control of heating, insulation, and cooling processes, ensuring consistency and repeatability of annealing quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

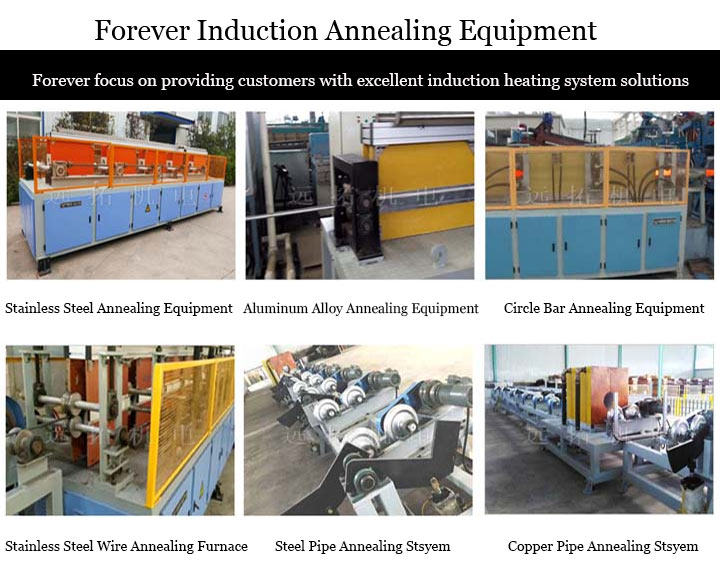

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 09-25-2024