To know more about steel heat treatment process

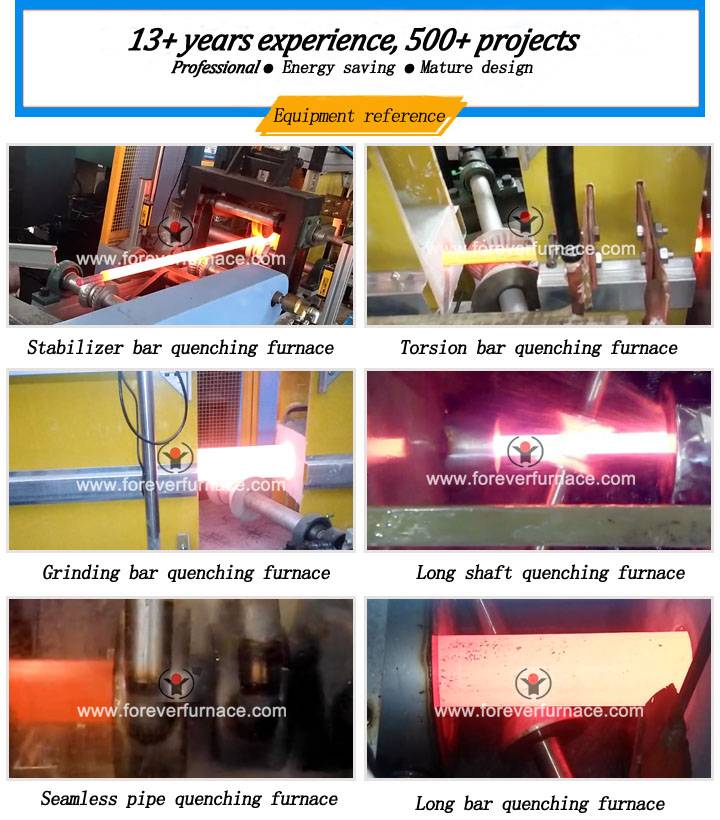

Specializing in the production of induction heat treatment furnace, Forever induction hardening and tempering equipment, induction annealing equipment, pipe induction heat treatment furnace has mature proven design and advanced induction heating technology, which has made Forever become top 3 manufacturer in China.

Induction heat treatment is the process of heating a metal material by heating, holding and cooling it in a solid state to change its structure and properties. Do you understand the technology of steel heat treatment process? The following is the simple introduction for different process of heat treatment.

Steel heat treatment includes the following several processes:

Steel heat treatment includes the following several processes:

1.Annealing: the metal or alloy materials or parts heated to the phase transition or partial phase transition temperature, hold for a period of time, and then slowly cooled.

2.Normalizing: the steel is heated to a certain temperature and maintain a period of time and cooled in the air.

3.Quenching: the steel is heated to phase change or partial phase transition temperature, to maintain a period of time and the rapid cooling.

4.Tempering: the steel is heated to a certain temperature and maintained for some time.

5.Quenching and tempering heat treatment: heating material, cooling liquid, and then heating. This composite process is known as quenched and tempered heat treatment process.

6.The surface heat treatment: By changing the surface chemical composition to change the surface properties of parts.

If you need steel induction heat treatment furnace, you should not only know the workpiece dimension and capacity but also familiar with the process of heat treatment including the hardness requirement, temperature requirement, tensile requirement and so on .

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating system in China; Glad to be your business partner in induction heating field.

Post time: 02-15-2018