Drill pipe induction heat treatment machine

Features:

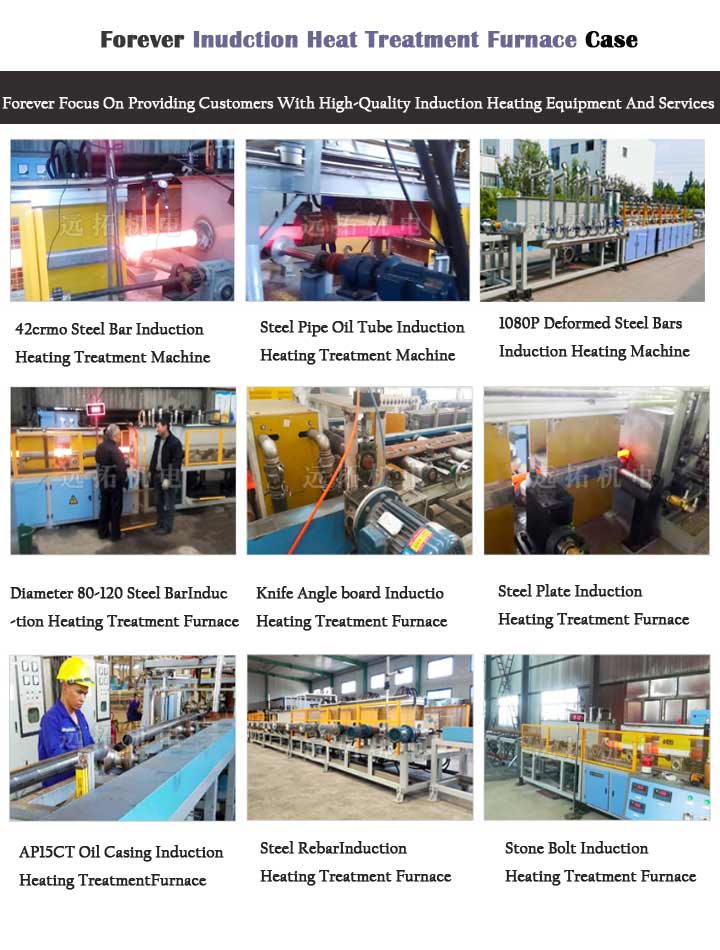

● Application: Heat treatment line for drill pipes, tubing, casing, OCTG

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

Forever is a leading manufacturer of drill pipe induction heat treatment machine in China. We have been devoting to the R&D and production of induction heat treatment equipment such as drill pipe induction heat treatment furnace, quenching and tempering furnace for petroleum tubing, quenching and tempering equipment for line pipe, quenching equipment for sucker rod and so on. We can customize the products according to the user’s needs.

The basic parameters of the drill pipe heat treatment machine are:

The basic parameters of the drill pipe heat treatment machine are:

● Equipment name: drill pipe heat treatment machine

● Equipment brand: Forever

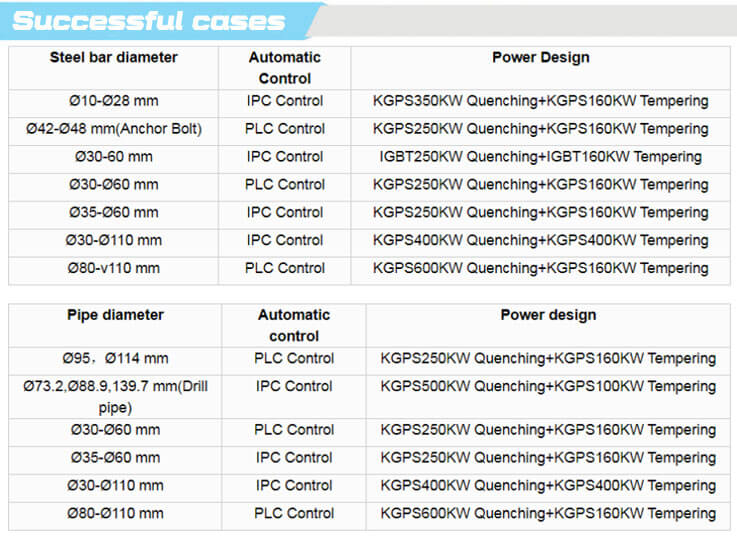

● Equipment technology: quenching+high temperature tempering

● Customized production: Yes.

● Application: quenching and tempering heat treatment technology used in drill pipe

● Heating way: Induction heating

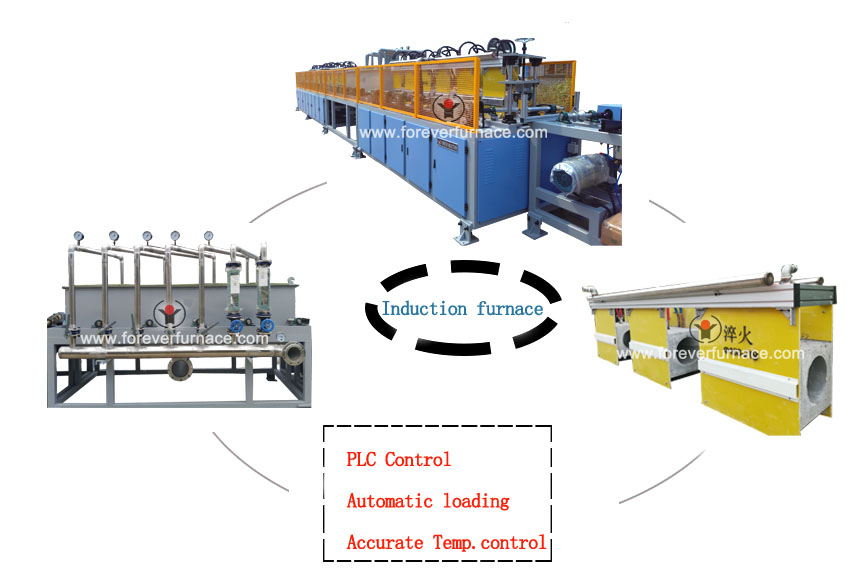

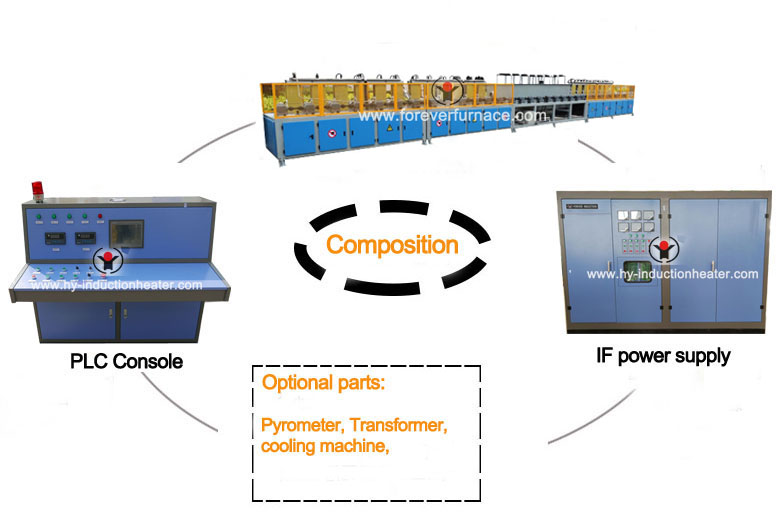

The basic components of the drill pipe heat treatment machine are:

The quenching automatic line includes: medium frequency power supply, capacitor cabinet, low temperature quenching heating inductor, high temperature quenching heating inductor, quenching cooling device (sprinkler, collector), sensor, infrared thermometer, PLC, industrial control computer, operating cabinet, double roller drive device, etc.

Tempering automatic line includes: intermediate frequency power supply, capacitor cabinet, tempering inductor, sensor, infrared thermometer, PLC, industrial control computer, operating cabinet, double roller drive device and so on.

The induction heating furnace is not only the copper coils, which are processed with annealing, roasting, double insulating, pouring refractory cement and so on and the inlet will be covered with copper plate to avoid magnetic leakage.

The mechanical transmission device includes: feeding table, double roller conveyor, draining device in the middle, translational turning device, bi-directional cooling bed, discharging table, discharging re-cooling roller, discharging re-cooling spraying device and so on. The mechanical transmission device uses frequency converter to adjust the speed and is controlled by PLC to realize the transmission speed required by the process.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Drill pipe heat treatment machine Welcome your inquiry for quenching and tempering induction heat treatment equipment !