Erw pipe heat treatment machine

Features:

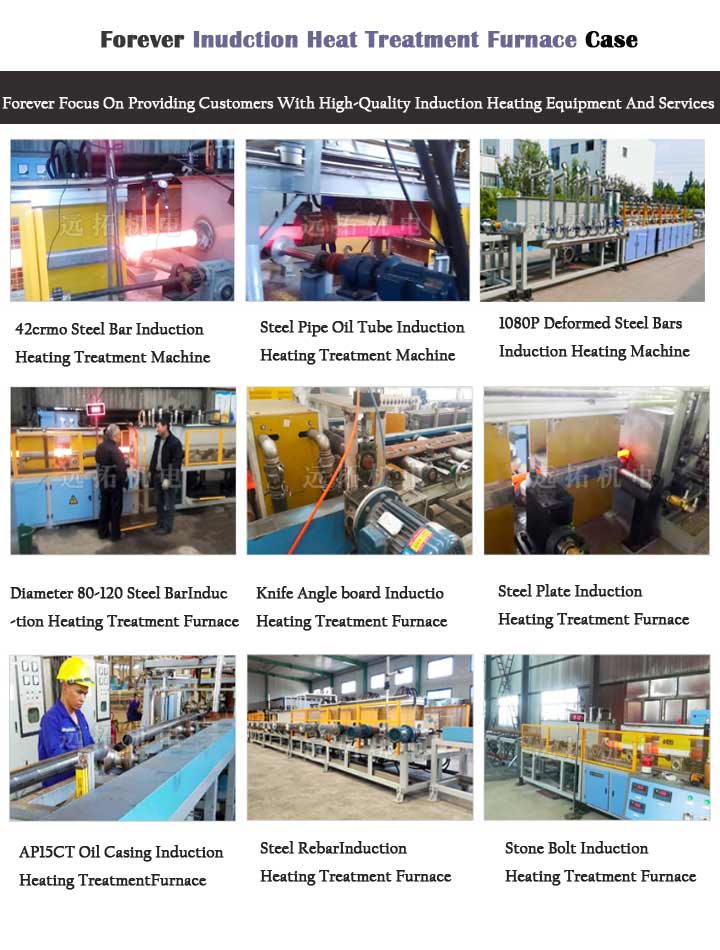

● Application: Heat treatment line for drill pipes, tubing, casing, OCTG, Erw pipe

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

Focusing on the development and production of erw pipe heat treatment machine, Forever products are of safety and reliability and energy saving 30% than traditional heating method. As we already have much proven design for the erw pipe heat treatment machine application in user’s plant, this Erw pipe heat treatment technology is very mature and reliable. The induction heat treatment equipment has stable performance, uniform heating, no bending and deformation after quenching and tempering. What’s more, we provide one year quality guarantee for the equipment.

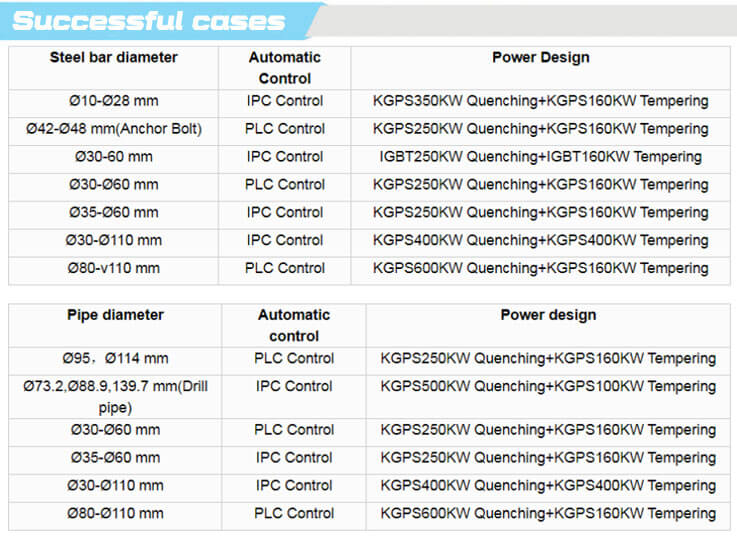

Technical parameters of erw pipe heat treatment machine:

● Name of equipment: erw pipe heat treatment machine(non-standard products)

● Equipment brand: Forever

● Size: workpiece with thickness greater than 2.0 mm

● Production efficiency requirements: as per user’s need

● Device power range: KGPS100KW-500KW

The characteristics of heat treatment furnace for tube billet quenching and tempering are:

The characteristics of heat treatment furnace for tube billet quenching and tempering are:

1. The erw pipe heat treatment furnace is fast and flexible, which has a high success rate.

2. Energy-saving and environmental protection, using medium frequency induction heating power supply control.

3. The Erw pipe has very high consistency and microstructure uniformity after heat treatment.

4. High toughness and impact strength will obtain after heat treatment.

5. No decarburization will occur during heat treatment.

6. It is very convenient to set up the state of the processing line that meets the needs of customers.

7. After induction heating, the workpiece has no crack, no deformation and toughness.

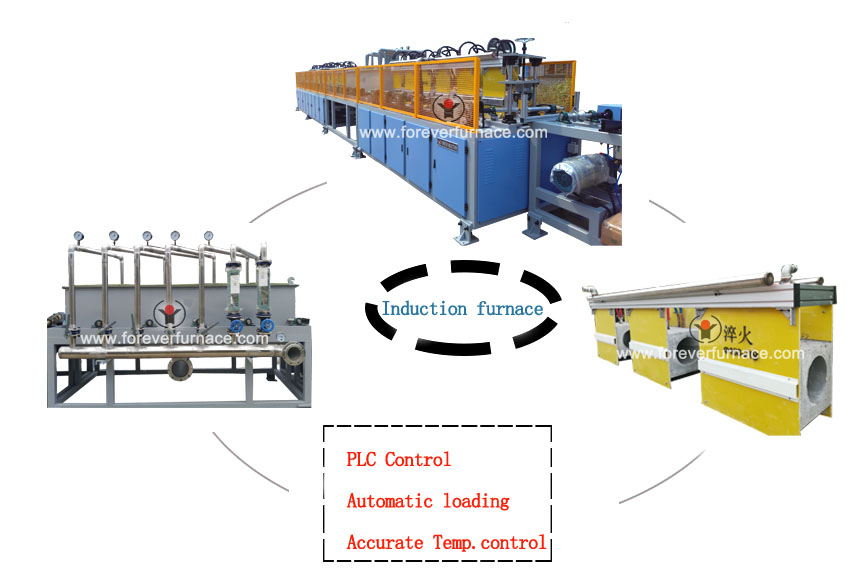

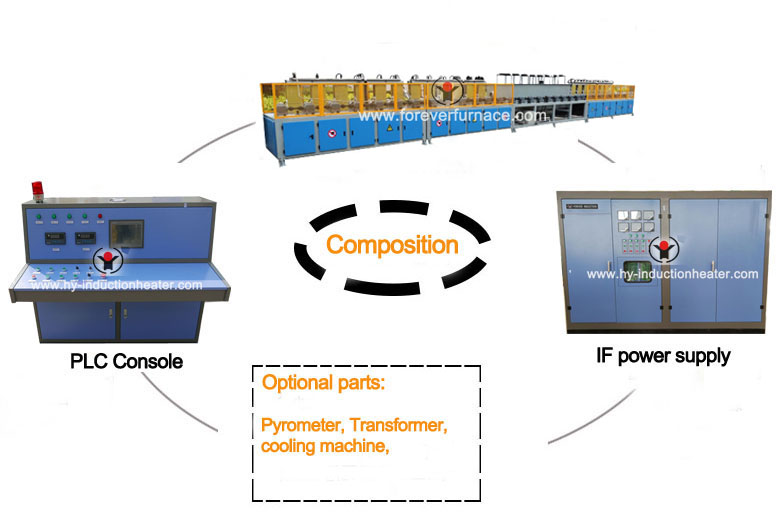

Induction hardening and tempering equipment is composed of feeding mechanism, feeding structure, induction heating system, quenching induction heating system, quenching spray system, tempering induction heating system, discharge system, PLC console, infrared temperature measuring device. The main console adopts Siemens PLC from Germany and Huayan Industrial Control System from Taiwan as the core control part, which automatically matches and adjusts the mechanical operation parameters.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !